Why Choose 1060 Precision-Ground Aluminum Rod?

1060 is a 1xxx-series commercially pure aluminum; trace copper improves machinability. Its properties directly address pain points in low-voltage power distribution and EV slow-charging components.

Leading electrical & thermal performance (62% IACS, ~210 W/m·K), reducing temperature rise in high-current busbars and charging terminals.

Excellent formability and weldability—deep drawing, stamping, and TIG/MIG welding without cracking.

Low density (2.70 g/cm³), ≥48% lighter than copper, lowering transport and installation costs.

Uniform grain structure and consistent anodized appearance, suitable for visible parts.

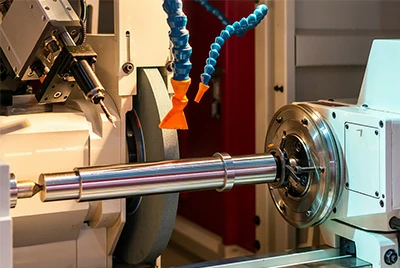

Precision Control (for CNC & Swiss-type)

Accuracy up to 0.02 mm — compatible with guide-bushing mode on Swiss-type lathes.

Straightness < 0.2 mm/m — stable with no vibration above 8,000 rpm.

Double-end chamfer — smooth, jam-free automatic bar feeding.

Turned bar head — pre-turned OD to fit limited-capacity collets/chucks.

Coarse-grain ring < 0.5 mm — prevents white spots/snowflake banding.

Improved machinability — optimized microstructure promotes chip breaking and boosts yield.

Chemical Composition

| Element | Limit (wt.%) |

| Si | ≤ 0.25 % |

| Fe | ≤ 0.35 % |

| Cu | ≤ 0.05 % |

| Mn | ≤ 0.03 % |

| Mg | ≤ 0.03 % |

| Zn | ≤ 0.05 % |

| Ti | ≤ 0.03 % |

| Zr | — |

| V | ≤ 0.05 % |

| Others | ≤ 0.15 % |

| Al | ≥ 99.60 % |

The lower the impurities (Fe, Si), the higher the electrical conductivity and corrosion resistance, and the longer the service life of the grinding media.

Mechanical Properties

| Temper | ensile strength σᵦ (MPa) | Yield strength σ₀.₂ (MPa) | Elongation A50 (%) | Shear strength (MPa) |

| H112 | ≥60 | ≥15 | ≥ 22 | - |

Physical Properties

| Property | Value (20 °C) | Note |

| Density | 2.70 g/cm³ | 48% lighter than copper |

| Melting range | 645–657 °C | Low melting point, easy to recycle |

| Specific heat | 0.900 kJ/kg·K | Heats up quickly, good heat dissipation |

| Thermal conductivity | 237 W/m·K | ~60% of pure copper |

| Coefficient of thermal expansion | 23.6 µm/m·K | Allow clearance for thermal growth |

| Electrical conductivity | 62% IACS | 0.034 Ω·mm²/m |

| Poisson’s ratio | 0.33 | — |

| Brinell hardness | 20 HB (O) / 46 HB (H18) | — |

1060 vs 1050 vs 6061 Comparison

| Alloy | Conductivity (% IACS) | Yield (MPa) | Density (g cm⁻³) | Cost index |

| 1060 | 62 | 25 | 2.7 | ★★ |

| 1050 | 61 | 20 | 2.7 | ★★ |

| 6061-T651 | 43 | 275 | 2.7 | ★★★ |

Processing & Manufacturing

Centerless Grinding Parameters

- Wheel surface speed: 40–60 m/s (white fused alumina / SiC)

- Workpiece speed: 100–200 m/min

- Feed: 0.04–0.07 mm/rev

- Grinding depth: 0.01–0.05 mm per pass; light, stepwise grinding to prevent burn

- Coolant: water-based emulsion + 2% oil; optional nano TiO₂ additive to reduce friction

Turning & Milling (1060 Aluminum Machining Data)

| Tool | Cutting speed (m/min) | Feed f (mm/rev) | Depth of cut ap (mm) | Recommended coating |

| HSS | 150–200 | 0.1 | 0.5 | — |

| Carbide | 250–350 | 0.15 | 1 | TiB₂ / DLC |

| DLC end mill | 350–500 | 0.05 per tooth | 1–3 | DLC |

Drilling: for Ø ≤ 10 mm use 40 m/min; for Ø ≥ 10 mm reduce to 20 m/min. Use a 135° point and evacuate chips regularly.

Surface Finishing

- Anodizing: current density 1.2 A/dm², film thickness 15 µm; bright silver or black anodize with high reflectivity.

- Mirror polishing: Ra < 0.2 µm, suitable for LED reflectors.

Typical Applications

EV charging infrastructure

Parts: charging handle/housing, charging terminals

Value: 62% IACS conductivity lowers contact resistance & temperature rise; good outdoor corrosion resistance

EV slow-charging systems

Parts: harness/busbars

Value: ≥ 48% weight reduction vs. copper, excellent formability & cost performance

Low-voltage power distribution

Parts: busbars, connector tabs

Value: adequate conductivity for low-voltage duty; lower hardness eases stamping to improve assembly efficiency

For scenarios requiring higher strength or fast-charging conditions, consider heat-treatable alloys such as 6061-T6 or 6101-T6. For low-voltage, slow-charging, and terminal components, 1060 remains a first choice thanks to its high conductivity, machinability, and low cost.

Frequently Asked Questions (FAQ)

Q: What are the differences among 1060, 1050, and 1070? A: Their minimum aluminum contents are 99.5%, 99.6%, and 99.7%, respectively. Higher purity yields higher electrical conductivity but slightly lower strength.

Q: Can 1060 precision-ground aluminum rods be used long-term in seawater? A: Yes. They have lower susceptibility to chloride-ion pitting than Al–Cu alloys and can be used directly in seawater heat-exchangers; anodizing with pore sealing is recommended to further enhance corrosion resistance.

Q: Can you provide SGS / RoHS / REACH documentation? A: Each batch ships with a COA. Upon request, we can arrange third-party testing by SGS, TÜV, or BV, and provide RoHS/REACH compliance statements.

Q: Can you deliver CNC-finished parts? A: Chalco offers one-stop services—cutting, drilling, mill-turn machining, and anodizing—for turnkey delivery.

Chalco Supply Capability

Stock sizes: Ø 6–100 mm, ~120 t on hand (overall tolerance ±0.05 mm, straightness 0.3 mm/m)

Minimum order: stock 25 kg; custom 100 kg

Grinding accuracy: diameter tolerance ±0.01 mm, roundness ≤ 0.015 mm

Quality system: ISO 9001:2015, IATF 16949, PED 2014/68/EU

Inspection equipment: optical emission spectrometer, eddy-current flaw detector, CMM

Packaging: pearl-cotton interlayers + moisture-barrier film + fumigated wooden crates; air/sea shipping supported

Contact & Ordering

Welcome to choose Chalco products! Contact us at sale@chalcoaluminum.com with your size, temper, and quantity. We will send the stock list, formal quote, and optimal logistics plan within 1 hour.

Chalco Aluminum — global 1060 precision-ground aluminum rod specialist.

In-stock ships in 3 days; custom orders delivered in 15 days.