Aluminum cladding panels are widely used in modern façades for their light weight, durability, and design flexibility. In real projects, cladding is not just about supplying panels—it is a complete wall system involving panel structure, connections, sub-frame design, joint detailing, and surface control.

To meet different façade installation methods, Chalco offers aluminum panels with edge folding, grooving, and back-bolt machining, ensuring seamless compatibility with ventilated façades, tongue-and-groove systems, vertical joints, and back-bolt installations for reliable performance and clean appearance.

Chalco Aluminum Cladding Panel display

Solid aluminum panel

A universal exterior wall panel for flat surfaces, folded edges, vertical joints, tongue and groove joints, and back-bolted systems; high strength and wide adaptability.

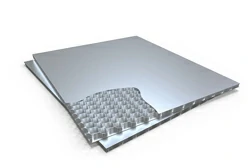

Aluminum honeycomb panel

Lightweight and highly rigid, suitable for exterior wall applications with large panel sizes and high flatness requirements.

3D Core / Beaded Core Panel

Combining lightweight and ultra-high rigidity, ideal for high wind pressure curtain walls, large sizes, and demanding structural stability conditions.

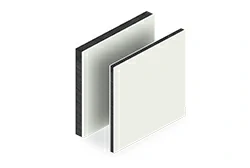

Insulated Sandwich Aluminum Panel

Integrated thermal insulation performance, ideal for exterior wall systems requiring both energy efficiency and structural integration.

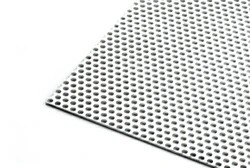

Perforated aluminum panel

Used for decorative, ventilated, or sun-shading façades; compatible with multiple façade system configurations.

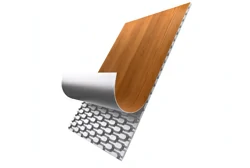

Irregularly shaped / bent aluminum panels

Suitable for tongue and groove joints, interlocking joints, vertical joints, and decorative applications, enabling greater design flexibility.

Chalco-Compatible Aluminum Cladding System Types

Rainscreen Ventilated Cladding System

The rear ventilation cavity improves moisture removal and weather resistance; requires high panel flatness and accurate edge folding. Chalco's solid, honeycomb, and 3D core panels are fully compatible with ventilated curtain wall systems.

Standing Seam Metal Cladding System

Continuous vertical seam lockstitch system suitable for large metal facades. Chalco's bendable solid aluminum panels offer excellent edge consistency and strong wind-pressure performance.

Interlocking / Shiplap Cladding System

Tongue-and-groove joints create a clean, tight linear façade. Chalco's solid and sandwich panels ensure precise edge geometry and rigidity for fast installation.

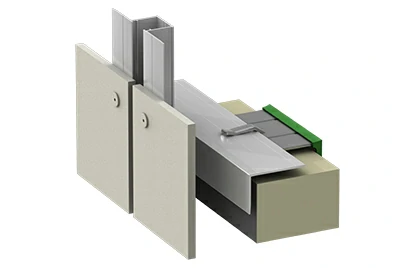

Hook-on / Back-Fastened Cladding System

Concealed fasteners or back bolts for large panels and high-wind zones. Chalco supports back-bolt holes, reinforcing ribs, and structural processing for high-rise curtain walls.

Large-Panel Façade System

Used in large public buildings where higher flatness and long-term stability are required. Chalco's honeycomb and 3D core panels ensure excellent performance in oversized façade applications.

Chalco Aluminum Cladding Panel Manufacturing Capabilities

From panel structure to finish system, ensuring engineering-grade stability of exterior wall panels.

- Solid panels, honeycomb panels, and three-dimensional core panels all undergo engineering-grade flatness and dimensional accuracy control.

- The constant temperature pressing and structural control process ensures the long-term structural stability of the honeycomb panel and the three-dimensional core panel.

- PVDF, powder coating, and anodizing strictly adhere to weather resistance and color difference management to maintain consistent project appearance.

- Batch production and surface consistency inspection ensure a continuous and stable supply of large curtain walls.

- Standardized large panel transportation and on-site protection plans reduce the risk of damage during handling and hoisting.

Chalco Aluminum Cladding Panel Fabrication & System Support

Make the panel easier, faster, and more stable to install in the field system.

- Precision CNC cutting, bending, and tongue-and-groove forming enable panels to accurately fit vertical joints, interlocking joints, and ventilated curtain wall systems.

- The structural processing, including back bolt holes, reinforcing rib welding, and edge reinforcement, is suitable for high-rise buildings and high wind pressure areas.

- Panel layout, edge dimensions, and node detailing support a systematic connection from design to manufacturing.

- For panel edges, tongue and groove joints, vertical joints, and back bolt nodes, it is recommended to improve the compatibility and installation efficiency between different systems.

- Planning for handling, stacking, and protecting large panels reduces on-site damage and improves installation controllability.

Chalco Aluminum Cladding Panel Applications & Reference Projects

Transportation Hubs & Airports: Chalco provides large-format honeycomb panels and 3D core panels to ensure high flatness and large-format layout of terminal building facades, and meets ventilation and large-format system requirements through structural stability control and system processing adaptation.

Commercial Complexes & Retail Façades: Solid aluminum panels combined with tongue-and-groove/insertion folded edges are used for commercial facades. Chalco achieves clear lines and long-term weather resistance through precise folding and consistent coating control.

Corporate Buildings & Office Towers: Large-format solid panels and three-dimensional core panels, combined with back bolt holes and reinforcing ribs, help high-rise curtain walls meet wind pressure, safety, and long-term structural performance requirements.

Public Buildings & Cultural Facilities: Perforated aluminum panels and ventilated curtain walls are used in exhibition halls and cultural buildings. Chalco provides stable bending and surface treatments to achieve a balance between decoration, sun shading and durability.

Industrial & Energy-Efficient Buildings: Insulated sandwich aluminum panels are used in industrial and energy-efficient buildings. Chalco achieves a stable composite of the insulation core material and the outer panel, meeting the requirements for insulation, weather resistance, and rapid assembly.

Transit Stations & Urban Infrastructure: Vertical joint systems and large panel panels are used for subway stations and municipal facades. Chalco provides a durable, uniform, and easy-to-maintain facade effect through folding precision and spraying stability.

FAQ

1. Which exterior wall systems can aluminum cladding panels be used for?

Chalco panels are compatible with ventilated curtain walls (Rainscreen), vertical joint systems, interlocking systems, back-bolt systems, and large panel curtain walls, and can be folded, shaped, and structurally processed according to different systems.

2. What thickness is typically used for exterior wall panels?

The common thickness of solid aluminum panels for exterior walls is 2.0–4.0 mm; for honeycomb panels and three-dimensional core panels, the overall structural strength is the main indicator. The specific thickness needs to be determined based on wind pressure, facade design, and system type.

3. What are the advantages of honeycomb panels and three-dimensional core panels compared to solid aluminum panels?

Both have higher flatness and structural rigidity, making them suitable for large-size panels or high wind pressure areas; the three-dimensional core board performs better in terms of bending resistance and structural stability.

4. Will there be batch-to-batch color differences in surface treatment?

Chalco implements batch-based color difference control in PVDF, powder coating, and anodizing systems and provides a sample confirmation process to ensure consistent appearance across large projects.

5. Can the panel be fitted with back bolt holes, folded edges, or reinforcing ribs?

Yes. Chalco offers services such as back bolt hole processing, reinforcing rib welding, edge banding, and tongue and groove forming, which can be directly used in high-rise and large-panel curtain wall systems.

6. Which projects are suitable for insulated sandwich aluminum panels?

Suitable for industrial buildings, energy-saving buildings, cleanrooms, and other scenarios requiring integrated external wall insulation, combining insulation performance with external wall finish.

7. What is the fire resistance rating of the exterior wall panels?

Depending on the panel structure, A2/non-combustible rating can be selected, making it suitable for engineering projects with strict fire protection requirements.

8. Does Chalco offer node de-emphasis or installation support?

Chalco can provide layout, edge dimensions, system node suggestions, and processing details to help improve system compatibility and installation efficiency (on-site installation services are not provided).

9. Given the large area of the panels, are there any risks involved in transportation and hoisting?

We provide advice on large panel transportation, stacking, protection, and on-site hoisting to reduce the risk of damage during construction and improve project controllability.

10. Can you make custom sizes or special shapes?

Yes. Solid panels, honeycomb panels, and 3D core panels can all be cut, bent, punched, or shaped as needed to match the design expression of the building facade.

Communicating with the Chalco engineering team to simplify the exterior wall system

Whether it's determining panel specifications, comparing surface finishes, or confirming system nodes and installation details, Chalco's engineering team can provide expert support for your project.

Contact us to give your facade project greater confidence in terms of structure, safety, and aesthetics.