Mechanical Properties Comparison: 6061 T6 vs 7075 T6

| Property | 6061-T6 | 7075-T6 |

| Tensile Strength | ≥290 MPa | ≥560 MPa |

| Yield Strength | ≥240 MPa | ≥500 MPa |

| Elongation | ≥8% | ≥5% |

| Hardness (HB) | ≈95 | ≈150 |

| Density (g/cm³) | 2.7 | 2.81 |

| Fatigue Strength | Medium | High |

| Cost | Low–Medium | High (~1.5× 6061) |

7075 offers superior mechanical strength but at higher cost and with more demanding machining requirements, while 6061 provides a balanced performance-to-cost ratio.

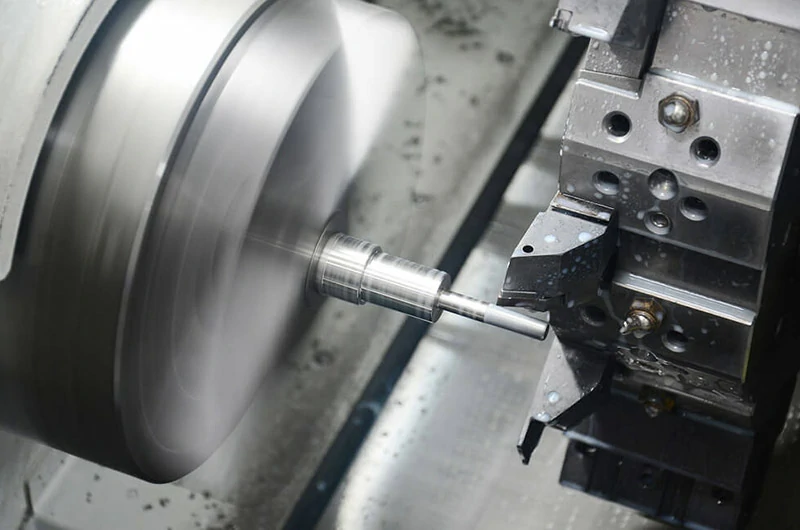

Machinability and Post-Processing Compatibility

6061 machines smoothly with lower cutting forces, suitable for high-speed, high-feed CNC environments. 7075's higher hardness requires rigid machines and wear-resistant tooling, with slightly lower overall efficiency.

6061 causes less tool wear and easily achieves Ra ≤ 1.6 μm surface roughness. 7075's short chips aid chip evacuation and can achieve fine finishes with optimized parameters, though tool wear is faster.

For anodizing, 6061 produces a uniform decorative or structural oxide layer. 7075's higher copper content can cause discoloration or spots, making it better suited for hard anodizing to improve corrosion and wear resistance.

In welding, 6061 is compatible with TIG and MIG processes, suitable for frames and enclosures. 7075 has poor weldability and is generally avoided for load-bearing welded structures.

Chemical Composition Comparison

| Element | 6061-T6 (%) | 7075-T6 (%) | CNC/Welding/Finishing Impact |

| Al | Balance | Balance | Base metal; 7075 generates more heat when cutting |

| Mg | 0.8–1.2 | 2.1–2.9 | Higher Mg increases hardness; more tool wear in 7075 |

| Si | 0.4–0.8 | ≤0.40 | Affects anodizing color; 6061 more uniform |

| Cu | 0.15–0.40 | 1.2–2.0 | Higher Cu increases strength, lowers corrosion resistance |

| Zn | ≤0.25 | 5.1–6.1 | Higher Zn increases hardening potential |

| Cr | 0.04–0.35 | 0.18–0.28 | Refines grain and improves stability |

| Fe | ≤0.70 | ≤0.50 | Low Fe improves elongation and fatigue life |

| Mn | ≤0.15 | ≤0.30 | Grain refinement in conjunction with Cr |

Typical Applications

| Industry | Key components | 6061-T6 | 7075-T6 |

| Aerospace | Wing spars, control-surface ribs, satellite bay frames, ground test fixtures | Welding-friendly. Suited to large frames. Post-MIG/TIG artificial aging 160 °C × 2 h. Anodizing ≥15 µm for corrosion resistance. | Ultra-high specific strength. Withstands alternating loads. Re-age after CNC finish milling to relieve residual stress. Hard anodizing ≥40 µm with sealing. |

| Automation & robotics | Linear-guide seats, servo-motor flanges, grippers and pivots | Fast cutting, Ra ≤0.8 µm. Anodize 10–15 µm (clear/black). Colored anodizing for visual parts. | High-torque joints and gearbox housings. H7/h6 fits. TiAlN tools, Vc 160–200 m/min. High rigidity to suppress chatter. |

| Motorsport & sporting goods | Suspension links,frame lugs/joints, carabiners | Cost-friendly. Suitable for batch welding (ER4043/5356). Post-weld aging to avoid softening. Color anodizing enhances brand identity. | Steering knuckles, hubs, UAV prop hubs. Forge–extrude–machine integration reduces defects. PTFE-impregnated hardcoat lowers friction. |

| Consumer electronics | Laptop top covers, smartphone mid-frames, heat-spreader bases | High-speed milling 25,000 rpm. Cu ≤0.4 % reduces color shift. Fine chamfer plus bead-blast improves hand feel. | High-strength thin brackets and module frames. Wall thickness ≥0.8 mm prevents warpage. Finish-milling plus re-aging preserves dimensions. |

| Molds & fixtures | Vacuum-forming molds, die-casting master molds, injection inserts | Good thermal conductivity, fast cooling. Cooling channels φ8–10 mm, pitch ≤25 mm. Hardcoat plus PTFE spray. | High-pressure injection cavities, CFRP pre-press plates. High compressive strength and heat-fatigue resistance. Post-hardcoat polish to Ra ≤0.4 µm. |

| Architecture & transportation | Roof racks, lightweight ladders, metro screen-door frames | Controllable cost, good weatherability. Twin-gun MIG for large members. Outdoor anodic film ≥15 µm. | Lightweight nodes and high-load hinges. High yield strength increases safety margin. Mechanical fastening replaces welding at critical locations. |

Dimensional Tolerances

| Nominal Diameter (mm) | h9 (mm) | h10 (mm) | h11 (mm) |

| 6 – 10 | −0.036 / −0.075 | −0.036 / −0.090 | −0.036 / −0.120 |

| 10 – 18 | −0.043 / −0.090 | −0.043 / −0.105 | −0.043 / −0.135 |

| 18 – 30 | −0.052 / −0.110 | −0.052 / −0.130 | −0.052 / −0.160 |

| 30 – 50 | −0.062 / −0.130 | −0.062 / −0.160 | −0.062 / −0.200 |

| 50 – 80 | −0.074 / −0.160 | −0.074 / −0.190 | −0.074 / −0.240 |

Chalco offers standard ±0.02 mm tolerances, with ±0.01 mm available for high-precision needs.

FAQs

Q:Which should I choose, 6061 or 7075?

A: For high strength and load-bearing, choose 7075. For machining efficiency, anodizing quality, and welding, choose 6061.

Q:Which is easier to CNC machine?

A: 6061 machines more easily and cost-effectively; 7075 requires careful tool and cooling management.

Q:What about anodizing differences?

A: 6061 yields a uniform bright oxide layer; 7075 benefits from hard anodizing.

Q:What tolerances can you provide?

A: Standard ±0.02 mm; custom ±0.01 mm available.

Q:What tooling is best?

A: 6061 works with standard tools; 7075 works best with TiAlN-coated tools, 150–250 m/min cutting speed.

Why Choose Chalco CNC-Turned Aluminum Bars?

- Global delivery to 60+ countries

- Custom tolerances to ±0.01 mm

- Full processing: turning, chamfering, polishing, anodizing

- Complete certifications: EN 10204 3.1, SGS, RoHS, ASTM

- Traceability with QR batch management and technical support

-

Contact Us

Email: sale@chalcoaluminum.com

WhatsApp: +86 17344894490

Send your drawings/specs for 1-on-1 engineering quotes and samples.