Discover how Chalco Aluminum transforms solid aluminum ingots into high-quality plates and coils through an advanced hot rolling process.

Our hot rolled products serve multiple industries with excellent mechanical properties, surface quality, and dimensional accuracy.

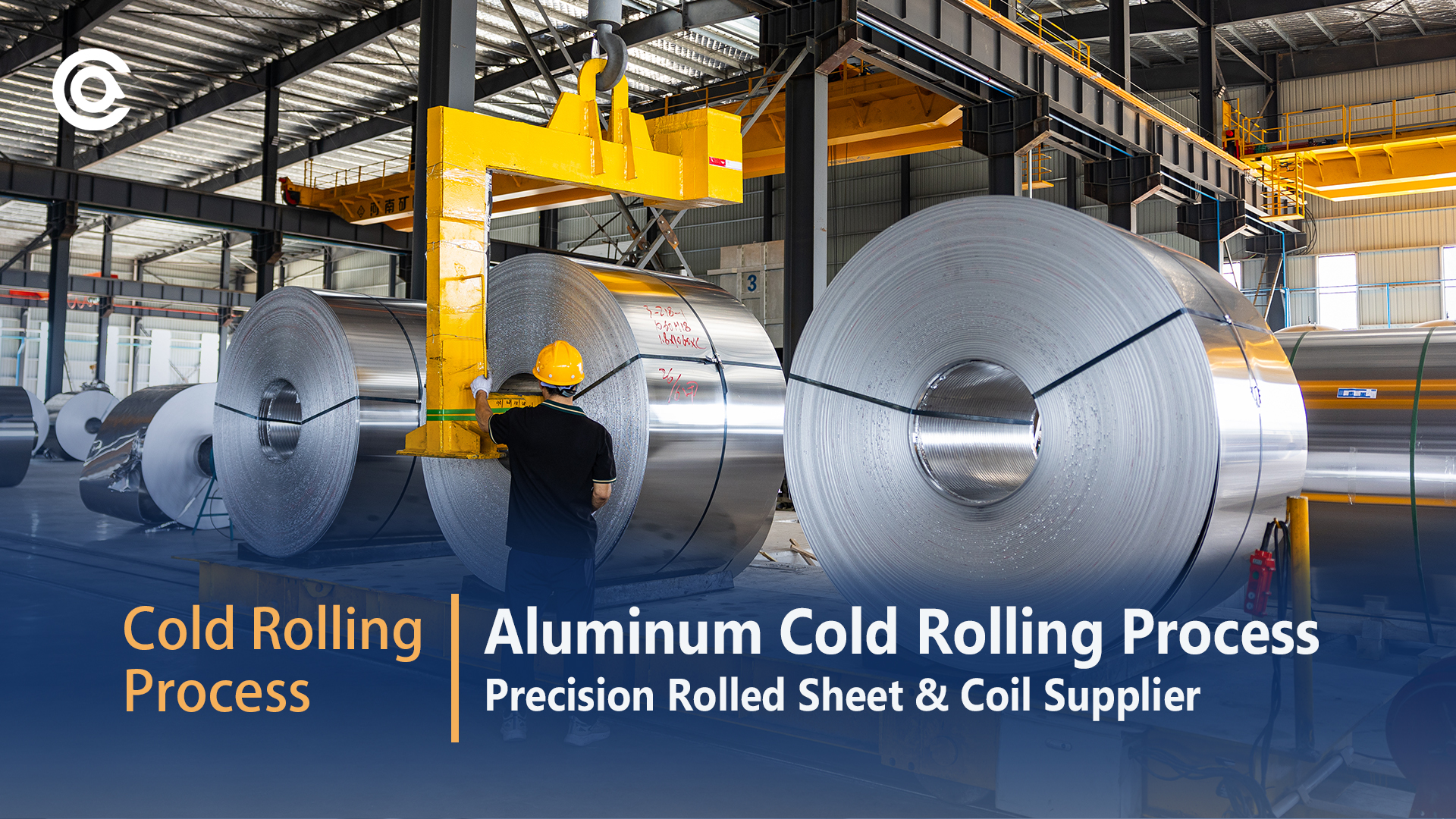

Hot Rolling Process Overview

The hot rolling process converts aluminum ingots into continuous plates and coils through a sequence of heating and rolling operations.

Key production steps include: Ingot Casting → Surface Milling → Preheating (Homogenization) → Rough Rolling → Finishing Rolling → Cooling → Coiling.

Each stage is carefully monitored to ensure uniform thickness, smooth surface, refined grain structure, and high strength — preparing the aluminum for downstream applications such as cold rolling, surface finishing, or direct industrial use.

Hot Rolled Aluminum Products

Chalco Aluminum produces hot rolled plates and coils in a wide range of 1xxx–7xxx series alloys, suitable for industrial and architectural applications.

These products feature excellent formability, strength, and surface finish, meeting international ISO and ASTM standards.

Our hot rolled aluminum can be customized in thickness, temper, and surface condition to meet diverse project requirements.

-

Industrial and structural plates

-

Transportation & marine sheets

-

Construction and curtain wall panels

-

Aerospace & machinery components

Quality Assurance & Delivery

All hot rolled materials are produced under ISO 9001 and AS9100 quality management systems.

Each coil is carefully packed and labeled to ensure safe global shipment with full traceability.