Aluminum tubes are widely used in aerospace and commercial industries, including healthcare products, entertainment products and machine parts. Aluminum tubes are respected by many manufacturers for their durability. Because aluminum tubes have both strength and flexibility, many applications benefit from these properties of aluminum tubes.Quick Quote

Advantages of purchasing Chalco aluminum tube pipes

- Chalco is the source factory of aluminum pipes and can provide you with extremely low factory prices.

- Chalco stocks aluminum tubes in various sizes, with a minimum order quantity of one tube, and can guarantee delivery within a week.

- Chalco aluminum tubes feature high straightness and precision. They can be produced in various forms, including cold-drawn tubes, extruded tubes, tapered tubes, seamed tubes, very thin wall tube, seamless tubes, Large diameter tube, forged tube.

- Aluminum tubes can be cut according to customer requirements or ordered separately from molds

- Chalco can send free aluminum tube samples Quick Quote

Applications of Aluminum Tubes & Pipe

Aerospace Applications Aluminum Tubes

Aluminum aircraft tubing is a type of high-strength, lightweight, and corrosion-resistant aerospace-grade aluminum alloy tubing widely utilized in the aerospace industry. The product standards include AMS 4083, AMS 4086, AMS 4087, and AMS 4088.

Chalco Aluminum Corporation (Chalco) can manufacture seamless extruded tubes in various custom dimensions using aluminum alloys such as 1100, 3003/6061, 5083/2014, 2024/2219, 5251, and 5052. With excellent quality, Chalco is a supplier of aerospace aluminum materials to renowned companies like Boeing and Airbus, including Collins Aerospace.Quick Quote

1100 Aerospace Aluminum Tube

3003 Aircraft Aluminum Tube

AMS 6061 Aluminum Tube

5083 Aerospace Aluminum Tube

2014A Aerospace Aluminum Tube

2024 Aircraft Aluminum Tube

2219 Aircraft Aluminum Tube

5251 Aircraft Aluminum Tube

5052 Aircraft Aluminum Tube

5083 Aircraft Aluminum Tube

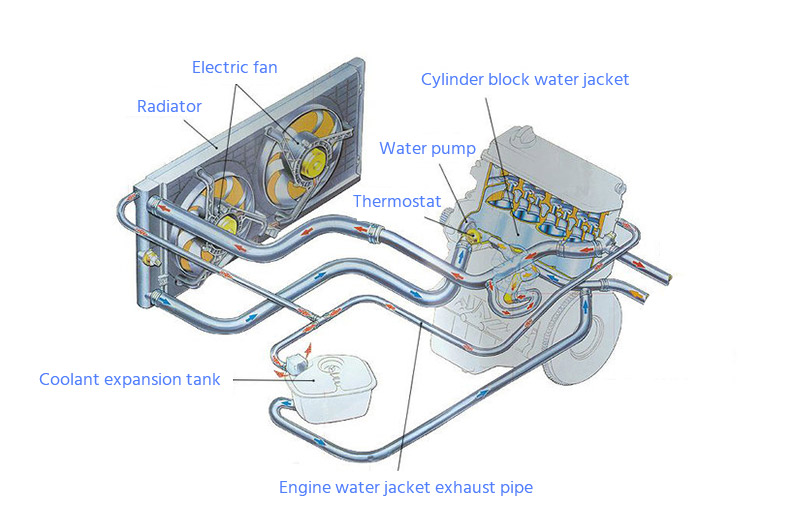

Transportation Aluminum Tubes

Chalco, a diversified aluminum products manufacturer, provides high-performance aluminum tubes for aerospace, shipbuilding, automotive, cycling, heat exchangers, and more, offering lightweight, corrosion-resistant solutions with alloys such as 5083, 6061, 5052, 7005, and 3003, supporting technological innovation and sustainability across various industries.Quick Quote

6063 Oil Tanker Aluminum Tube

6061 Oil Tanker Aluminum Tube

AMS 6061 Aluminum Tube

6061 Aluminum Tube for Bicycle

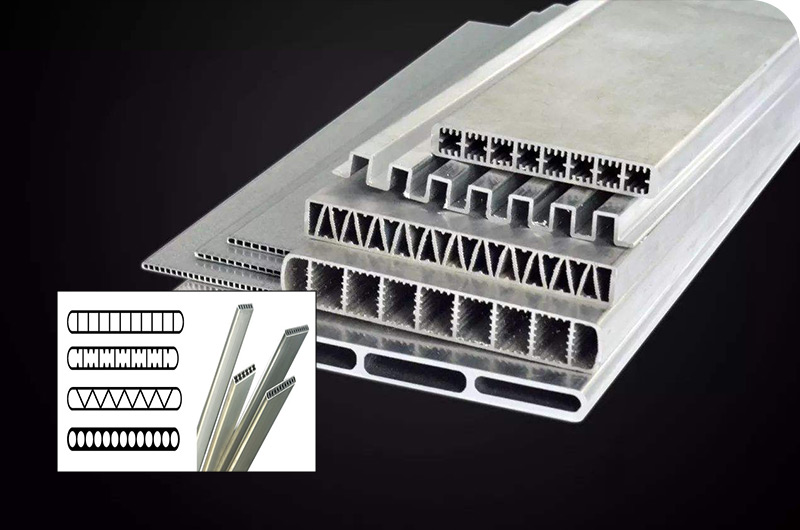

Tubes for Heat Exchanger

Missile-launcher-tube

Auto-welded-tube

Auto-micro-channel

3003-auto-tube

1100-auto-tube

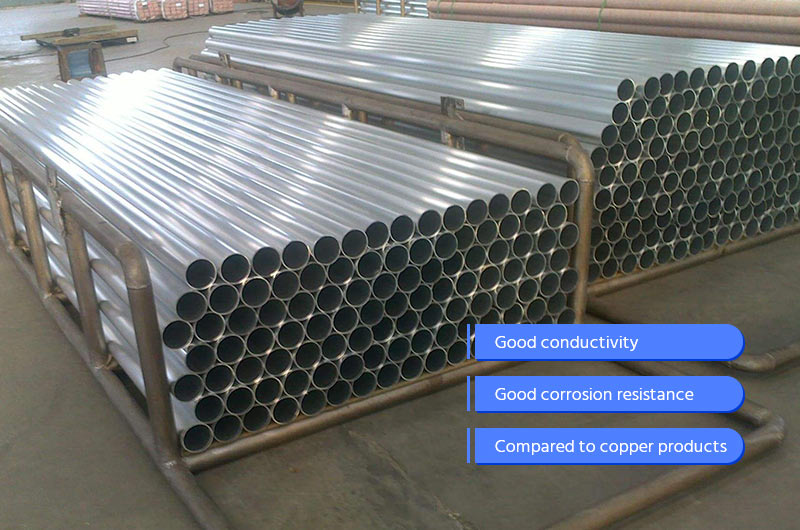

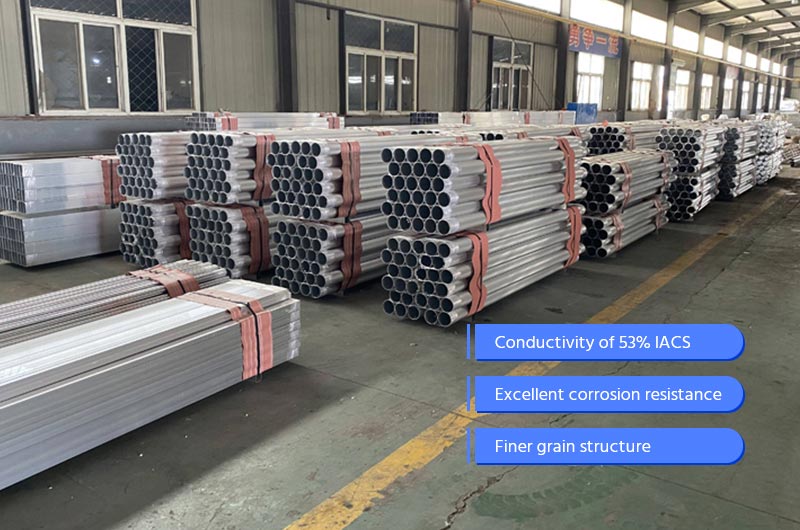

Electric aluminum tube

Chalco tubular aluminum busbar products cover popular alloy series such as 1350, 1060, 1070, 3003, 6061, 6063, and 6101, with strong conductivity and corrosion resistance. After anodizing, they can adapt to various outdoor environments.

The product is delivered in a tubular structure, with straight body, smooth and flat surfaces, and no defects such as cracks, wrinkles, twists, etc. Compared with other shapes of busbars, they are lighter in weight, larger in cross-sectional area, stronger in load-bearing capacity, and more convenient to install.Quick Quote

-

Electrical-aluminum-bus-pipe

Chalco tubular aluminum busbar products cover popular alloy series such as 1350, 1060, 1070, 3003, 6061, 6063, and 6101, with strong conductivity and corrosion resistance. After anodizing, they can adapt to various outdoor environments.

Strong conductivity Corrosion resistance Straight body

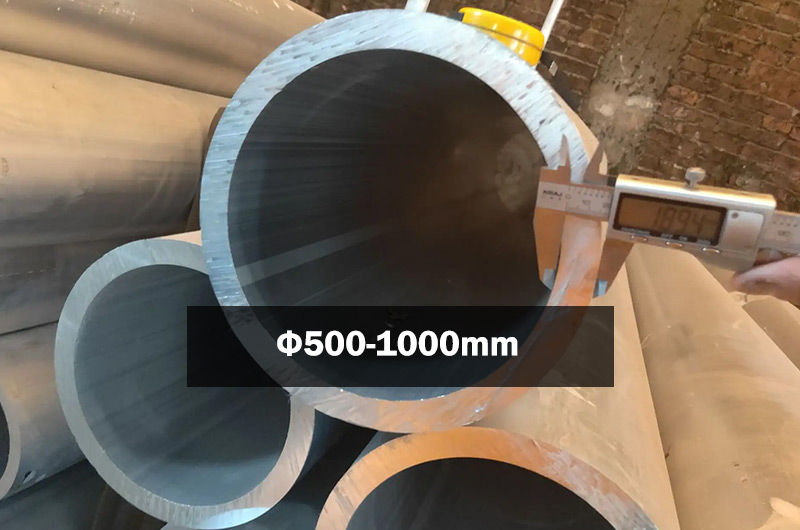

Special Size Aluminum Tubes

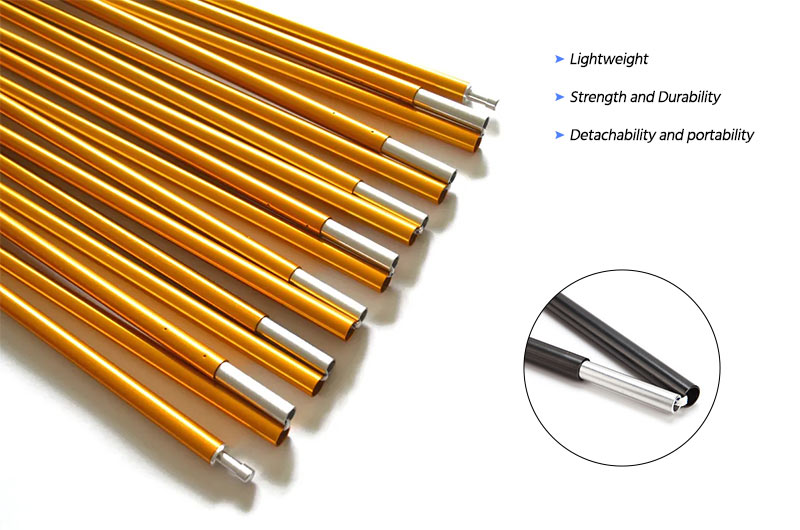

Chalco specializes in a diverse range of aluminum products, including cold-drawn tubes, extra-large diameter aluminum tubes (500mm-1528mm), ultra-hard wear-resistant cylinder tubes, spiral welded tubes, tent poles, streetlight poles, and gas cylinder tubes.Quick Quote

With exquisite craftsmanship and superior quality, Chalco's products cater to various industries, offering innovative and sustainable aluminum solutions.

Cold Drawn Aluminum Tubing

Large Diameter Aluminum Pipe

SCH40/SCH80 Aluminum Tube

Large Diameter Aluminum Pipe

Pneumatic-cylinder-tube

Tent-pole

Aluminum-gas-cylinder-tube

Street-light-aluminum-pole

Apiral-welding-pipe Max. Φ1580mm

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we

will be your best choice.

Lowest offerFree sample

Contact us Now

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.

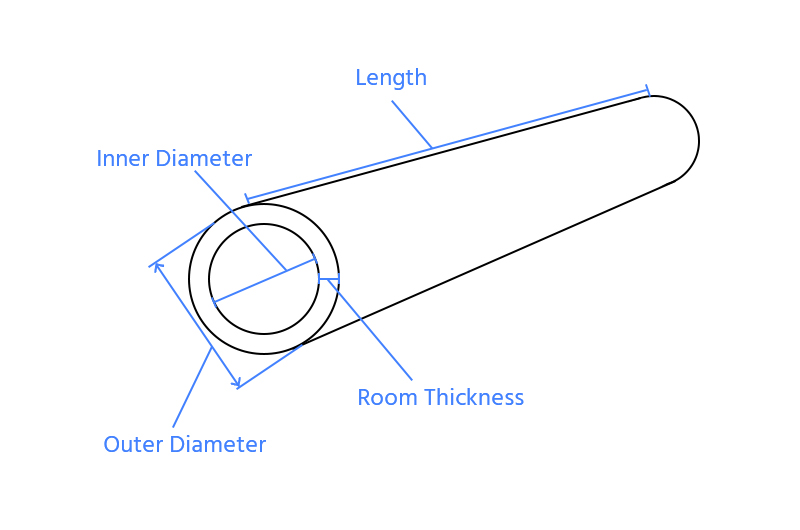

Common specifications of aluminum round pipe

The outer diameter of aluminum tube is generally about 4 to 300 mm, and its wall thickness is mostly between 0.25 and 40 mm. Common aluminum pipe specifications are φ twenty-five × 6, φ thirty × 4, φ thirty-two × 2.7, φ thirty-seven × 11, φ thirty-eight × 8, φ forty-three × 14 etc. There will also be difference among the specifications of different aluminum material types. For example, the wall thickness and outer diameter of thin-walled round aluminum tubes are mostly about 20 to 130 mm, and the outer diameter of thick walled round aluminum tubes are mostly about 15 to 160 mm.Quick Quote

Common series of chalco aluminum tubes

1000 series aluminum pipe

The common alloy of 1000 series aluminum pipe: 1050, 1060, 1070.

1 series aluminum is industrial pure aluminum. It has high plasticity, corrosion resistance, electrical conductivity, thermal conductivity and other characteristics. But the strength is low, the heat treatment cannot be strengthened, and the machinability is poor. It can be used for gas welding, hydrogen atom welding and contact welding, but is difficult to braze. 1 series aluminum is easy to bear various pressure processing, extension and bending.

2000 series aluminum pipe

The common alloy of 2000 series aluminum pipe: 2014, 2017, 2024, 2A12, 2219, 2A11, 2A14, 2A50.

2 series aluminum alloy has good machinability and good performance of contact welding, spot welding and roll welding. However, the performance of electric arc welding and gas welding is poor. It can be strengthened by heat treatment and has extrusion effect.Quick Quote

It is applied to occasions requiring high strength and hardness (including high temperature), such as aircraft heavy, forgings, thick plates and extruded materials, wheels and structural elements, first stage fuel tank of multistage rocket and spacecraft parts, truck frame and suspension system parts, etc.

-

2024-aluminum-round-tube

OD: 0.20"-29.37"

Wall: 0.01"-3.94"

Length: customizable

High strength and light weight

-

2024-aluminum-square-tube

OD: 0.20"-20"

Wall: 0.02"-2"

Length: customizable

High strength and light weight

3000 series aluminum pipe

The common alloy of 3000 series aluminum pipe: 3003, 3A21.

This kind of aluminum tube has good formability, dissolution and corrosion resistance.

It is used for processing parts with good formability, high corrosion and weldability. It can also be applied to work applications that require both these properties and higher strength than 1000 series alloys.

-

3003 aluminum tube

OD: 0.125"-0.25"

Wall: 0.025"-0.065"

Length: customizable

excellent corrosion resistance, processing capabilities

-

3003 Cold Drawn (Rolled)

Seamless Tubes

OD: 10-120mm

Wall: 0.5-25mm

Length: 1000-40000mm

good thermal conductivity and electrical conductivity

Kitchenware, food and chemical product handling and storage devices, slot and tanks for transporting liquid products, various pressure vessels and pipes processed with thin plates, radiator, vanity board, photocopier drum, marine materials.

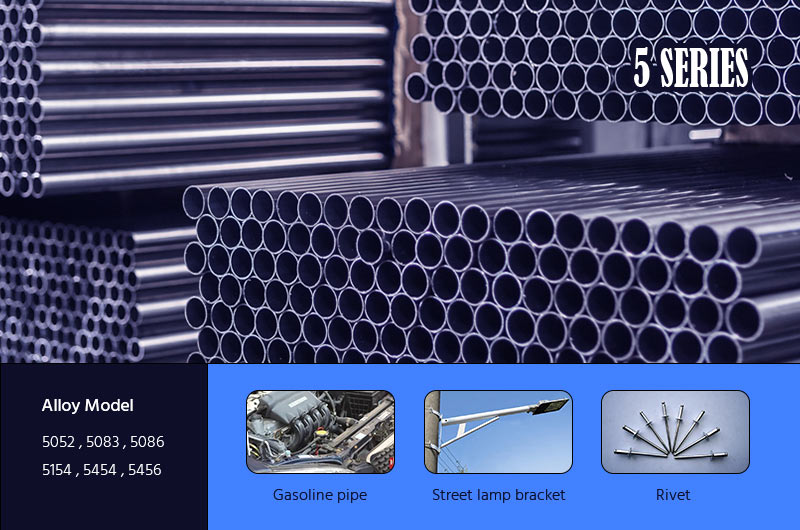

5000 series aluminum pipe

The common alloy of 5000 series aluminum pipe: 5052, 5083, 5086, 5154, 5454, 5456.

The 5 series aluminum pipe is the Al-Mg series alloy. It is the most widely used antirust aluminum. This alloy has high strength, especially the fatigue strength: high plasticity and corrosion resistance, can not be strengthened by heat treatment. The plasticity is good in semi-cold work hardening, but low in cold work hardening. Good corrosion resistance, good weldability, poor machinability, and polishable.Quick Quote

-

5052 O H112 Tubing

OD: 0.125"-13.701"

Wall: 0.02"-1.772"

Length: customizable

low and medium pressure hydraulic systems, fuel lines

-

5083 Aluminum Pipe

OD: 6.693"-9.055"

Wall: 0.394"

Length: customizable

excellent welding characteristics, outstanding corrosion resistance

-

5086-aluminum-pipe

OD: 0.54"-12.75"

Wall: 0.09"-0.69"

Length: customizable

High strength and high corrosion resistance

It is mainly used in occasions requiring high plasticity and good weldability. Low load parts working in liquid or gas medium, such as oil tank, gasoline or lubricating oil pipe. Various liquid containers and other small load parts made by deep drawing, such as wire rods are used to make rivets. It is also commonly used for sheet metal parts of traffic vehicles and ships, instruments, street lamp brackets and rivets, hardware products, electrical enclosures, etc.

6000 series aluminum pipe

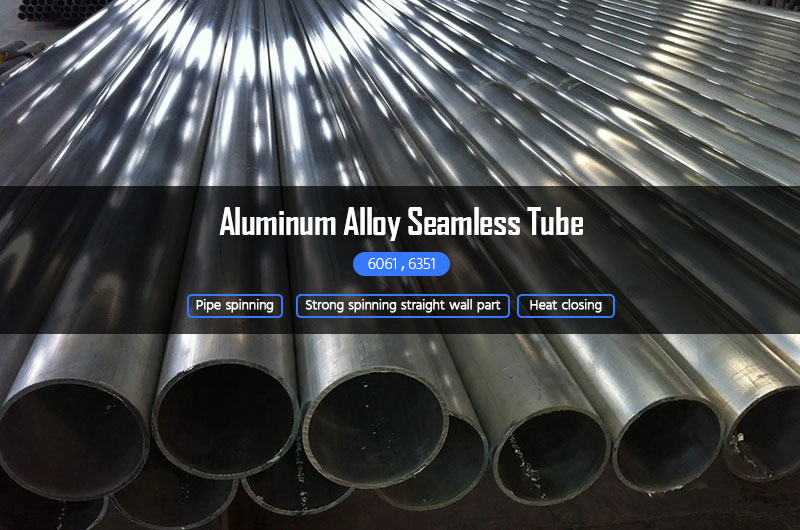

The common alloy of 6000 series aluminum pipe: 6005, 6105, 6041, 6042, 6061, 6351, 6082, 6162, 6262, 6064, 6063, 6066, 6A02 Quick Quote

-

6060 Aluminum Tube

OD: 1-1000mm

Wall: 0.1-100mm

Length: customizable

Excellent machinability

-

6061 Aluminum Tubing

OD: 0.709"-23.622"

Wall: 0.197"-3.937"

Length: customizable

Workability and excellent welding performance

-

6061 T6 Aluminum

Square Tubing

OD: 0.5"-8"

Wall: 0.065"-0.787"

Length: customizable

Easy to process, excellent welding performance

-

6063 T5 T6 Extruded

Aluminum Tubing

OD: 0.236"-23.622"

Wall: 0.039"-0.394"

Length: customizable

Corrosion resistant, easy to heat treat, anodize and weld

-

6063-aluminum-square-tube

OD: 0.394"-7.874"

Wall: 0.039"-0.236"

Length: customizable

Excellent corrosion resistance and processing properties

-

6082-aluminium-tube

OD: 0.236"-6"

Wall: 0.028"-0.5"

Length: customizable

Excellent corrosion resistance

6005 aluminum tube is a high-quality aluminum alloy product produced by heat treatment and pre-stretching process. Its strength cannot be compared with that of series 2 or 7, but it has many characteristics of magnesium and silicon alloys. It has excellent processing performance, excellent weldability and galvanicity, good corrosion resistance, high toughness and no deformation after machining, the material is dense and free from defects, easy to polish, easy to color film, excellent oxidation effect, and some other excellent features.

6 series aluminum tubes are generally used in electronic appliances. It is mainly used in various fields such as bus, stringing, conductors, electrical components, refrigerators, air conditioners, cables.

Representative applications include aerospace fixtures, electrical fixtures, communications, etc.

7000 series aluminum pipe

The common alloy of 7000 series aluminum pipe: 7050, 7075, 7178, etc.

Temper: T6, T651.

Standard: GB, GJB, ASTM, EN.

Aviation super hard aluminum alloy, with high strength and good wear resistance.

-

7075 Aluminum Tubing

OD: 0.906"-9.843"

Wall: 0.049"-1.575"

Length: 1500-4000mm

low and medium pressure hydraulic systems, fuel lines

7050 is a high strength heat treatable alloy. It is a kind of aviation super hard aluminum alloy, with high strength and good wear resistance. It has extremely high strength and resistance to peeling corrosion and stress corrosion cracking. It is commonly used in aircraft structural parts for medium and thick plate extrusion parts, free forging parts and die forgings.

We also have aluminum tubes available in other grade and sizes. Feel free to inquire for more information.Quick Quote

The difference between seamless aluminum tubes and seamed aluminum tubes

The seamless aluminum tube has better pressure bearing than the seamed aluminum tube. The texture of the seamless tube is relatively uniform. The chemical composition of the welded tube will be burnt a little at the weld part, so the mechanical properties are slightly worse but not very different. If it is used for bending pipe, it is recommended to use a seamless aluminum pipe. The welded pipe is easy to crack. There is no problem if the bending radius is relatively large. The seamless aluminum tube is formed by perforation extrusion, while the conventional aluminum tube is generally extruded with a combined die. In the production, short rod, high temperature, the slow extrusion process is used, especially when the "three temperatures" must be well controlled.

The aluminum ingot processing method used for seamless aluminum alloy tubes and seamed aluminum alloy tubes is different. Seamless aluminum tubes use surface turning, and seam aluminum tubes use non-oxidized scale incorporation.

In terms of mechanical properties, seamless aluminum pipe products have uniform metal flow at the beginning and end, high dimensional accuracy, good fatigue resistance, consistent mechanical properties, and no lamellar structure. The metal flow at the beginning and the end of the seamed aluminum tube product cannot be uniform, the mechanical properties are inconsistent, and the layered structure is easy to appear. On the whole, it is better to choose a seamless aluminum tube, but you also need to determine the choice according to your own situation.

Two important characteristics of aluminum tube: bending and connection

Three Main Factors for Aluminum Elbow

1. Formability

Some aluminum alloys, such as 3000, 5000 and 6000 series, have higher formability than other aluminum alloys, making them good bending materials. Generally, alloys with higher formability have lower strength.

2. Thickness and Bending Radius

Like other metals, aluminum will appear "work hardening" during bending. This means that it will become stronger and stronger when formed. However, if ratio of radius to pipe thickness is too small, the material will be over machined and more likely to lose efficacy.

3. Rate of Elongation

Percentage of elongation is a way of describing the difference between the yield strength of a metal and its ultimate tensile strength. Yield strength is the point at which an aluminum alloy can be bent and no longer restored to its original shape. The greater the difference between these strengths, the better the formability of the alloy.

Connecting pipe usually means that one pipe is connected to another pipe or one end is connected to a container. Most commercially produced tubes can be equipped with connectors designed for specific types, shapes, and sizes of tubes.Quick Quote

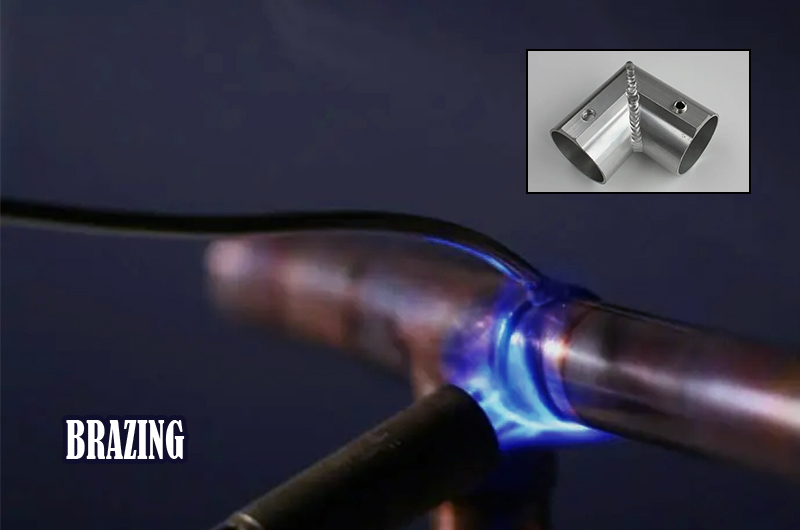

Brazing and welding of aluminum pipe

Welding is to join metals by melting and fusing metals, with filler material be added. Fusion need to concentrate the heat directly at the joint, and the temperature must exceed the melting point of the metal and filler. Welded joints are usually as strong as the base material.

The difference between brazing and welding is that the temperature is much lower and does not melt the base metal. Instead, the heat source melts the filler metal and draws it into the joint through capillary action. It forms a metallurgical combination between the filler metal and the part surface.

As with welding, joint strength usually exceeds the strength of individual parts. For example, the tensile strength of stainless steel joints can exceed 130000 psi. However, due to the low brazing temperature, usually 1150 to 1600 ° F, most physical properties are not affected. Deformation and warping are minimized, which minimizes the stress in the joint area.

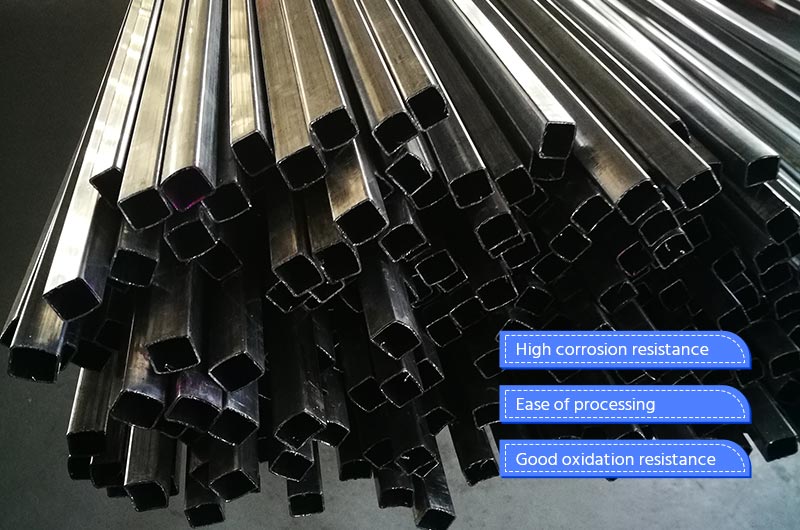

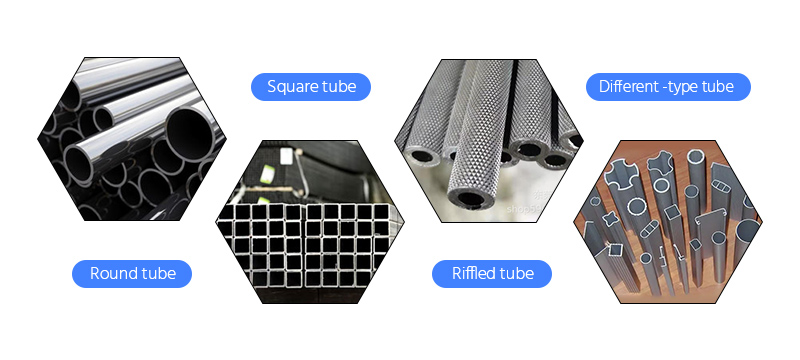

Four classification methods of aluminum tubes

By shape: square tube, round tube, embossed tube, profiled tube, globe aluminum tube.

By extrusion method: seamless aluminum tube and ordinary extruded tube.

By precision: ordinary aluminum tube and precision aluminum tube.Quick Quote

Precision aluminum tubes generally need to be re-processed after extrusion, such as cold drawing, fine drawing and rolling.

By thickness: ordinary aluminum tube and thin-walled aluminum tube.

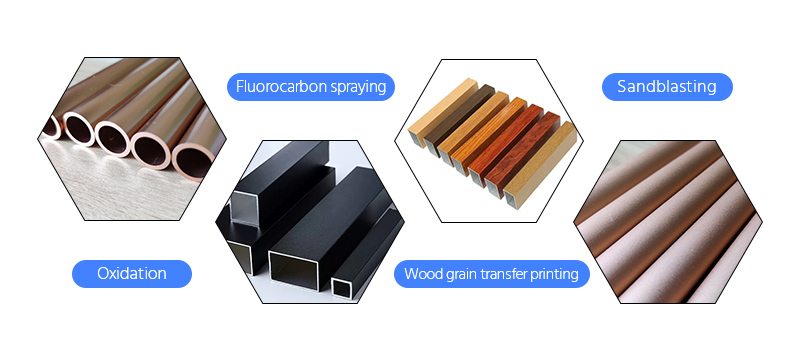

Two kinds of surface treatment methods for chalco aluminum tube

Chemical treatment: Oxidation, electrophoretic coating, fluorocarbon coating, powder coating, wood grain transfer printing.

Mechanical treatment: mechanical drawing, mechanical polishing, sandblasting.