Cold drawn (CF) aluminum rod is produced through a cold drawing process, repeatedly drawing it to achieve the desired diameter. The multiple drawing processes result in a perfectly smooth surface and high precision.

Our cold drawn aluminum rod has a tolerance of less than -0.03mm, straightness less than 0.3mm/m, true roundness of 0.01mm, good material consistency, and chamfered ends that do not catch material. It is suitable for applications with relatively weaker tolerances and diameter dimensions, especially on CNC machine tools with spindle speeds above 5000.

Chalco's hot-selling Precision Cold Drawn Aluminum Rod Bar

2011 Cold Drawn (CF) Aluminum Rod Bar

Temper: T3

Diameter: 0.125”-3.75” (3-100mm)

Length: 2m, 2.5m, 3m (up to 6m, customizable cutting)

Standards: DIN EN 754, ASTM B211, QQ-A-225/3

The 2011 Cold Finished Aluminum Rod Bar is well-known for its outstanding machinability, particularly in the Cold Finished state, making it one of the most easily machinable aluminum alloys with excellent mechanical performance. However, its welding characteristics are poor, making it unsuitable for brazing and soldering.

The 2011 Cold Roll Aluminum Round Bar finds wide applications in various fields such as screw machine products, fittings, atomizers, and hose components. It is also used in automotive fuel system components, precision gears, mechanical parts, tubing, and TV accessories.

Straightness and Tolerances of 2011 Precision Cold Drawing Aluminum Rod

| Diameter Tolerance | Straightness | True Roundness |

| -0.03mm | 0.3mm/m | 0.01mm |

2017 Cold Drawn (CF) Aluminum Rod Bar

Temper: T3, T351, T4, T451, T6, T651

Diameter: 0.125”-3.75” (3-100mm)

Length: 2m, 2.5m, 3m (up to 6m, custom cutting available)

Standards: DIN EN 754, ASTM B211, QQ-A-225/5, AMS 4118

2017 Precision Cold Finished Aluminum Rod Bar is renowned for its outstanding cutting performance and high strength, making it widely utilized in automatic screw processing. Its toughness and ductility make it suitable for manufacturing heavy-duty structural components, offering slightly lower strength than 2014 with superior fatigue strength.

Particularly, the 2017 T451 T6 aluminum rod finds extensive applications in high-strength structural fields such as aerospace, mechanical manufacturing, hydraulic components, screw machines, military equipment, rivets, and sports equipment.

Straightness and Tolerances of 2017 Precision Cold Drawing Aluminum Rod

| Diameter Tolerance | Straightness | True Roundness |

| -0.03mm | 0.3mm/m | 0.01mm |

2024 Cold Drawn (CF) Aluminum Rod Bar

Temper: T351, T851, T4

Diameter: 0.125”-3.75” (3-100mm)

Length: 2m, 2.5m, 3m (up to 6m, custom cutting available)

Standards: DIN EN 754, ASTM B211, QQ-A-225/6, AMS 4120, AMS 4339

2024 CF Aluminum Rod Bar is known for its high strength, good formability, and machinability, making it suitable for applications that demand high strength and precision performance, such as aircraft parts, truck wheels, hardware, and clock components. Although its formability is generally considered better in the cold state, it remains popular in applications like cold heading and thread rolling.

The 2024 Precision Cold Drawing Aluminum Rod Bar achieves high surface finish, exhibits good corrosion resistance, and finds wide applications in aerospace components, aircraft rivets, medical equipment appearance parts, optical instrument components, and more.

Straightness and Tolerances of 2024 Precision Cold Drawing Aluminum Rod

| Diameter Tolerance | Straightness | True Roundness |

| -0.03mm | 0.3mm/m | 0.01mm |

5052 Cold Drawn (CF) Aluminum Rod Bar

Temper: TF, O, H111, H14, H16

Diameter: 0.125 "-3.75" (3-100mm)

Length: 2m, 2.5m, 3m (maximum length of 6m, customizable for cutting)

standard:DIN EN 754, ASTM B211, QQ-A-225/7, AMS 4114

5052 Precision Cold Drawing Aluminum Rod Bar belongs to the AL-Mg series and is a widely used anti-rust aluminum rod. It has high strength, fatigue strength, high plasticity, and excellent corrosion resistance.

This alloy is suitable for manufacturing low-load parts such as rivets for aircraft fuel tanks, liquid containers, and automotive parts. It is also used in transportation vehicles, ship components, anchor bolts, CNC milling machines, fasteners, instruments, and hardware products.

The 5052 CF Aluminum Rod Bar performs exceptionally well in applications that demand high plasticity, good weldability, and corrosion resistance.

Straightness and Tolerances of 5052 Precision Cold Drawing Aluminum Rod

| Diameter Tolerance | Straightness | True Roundness |

| -0.03mm | 0.3mm/m | 0.01mm |

6061 Cold Drawn (CF) Aluminum Rod Bar

Temper: O, T4, T6, T651

Diameter: 0.125 "-3.75" (3-100mm)

Length: 2m, 2.5m, 3m (maximum length of 6m, customizable for cutting)

standard:DIN EN 754, ASTM B211, QQ-A-225/8, AMS 4115, AMS 4116, AMS 4117

6061 Precision Cold Drawing Aluminum Rod Bar is a heat-treatable general-purpose alloy rod with good formability, high corrosion resistance, and moderate strength. It can be hardened through heat treatment, and its strength is comparable to low carbon steel. Therefore, it finds widespread applications in areas such as truck components, sailboats, and chemical equipment.

The versatility of 6061 CF Aluminum Rod Bar makes it an ideal choice for various applications, including bicycle frames, fishing reel components, pipe fittings, fasteners, needles, suppressors, and more.

Straightness and Tolerances of 6061 Precision Cold Drawing Aluminum Rod

| Diameter Tolerance | Straightness | True Roundness |

| -0.03mm | 0.3mm/m | 0.01mm |

6063 Cold Drawn (CF) Aluminum Rod Bar

Temper: T4, T6, T66

Diameter: 0.125 "-3.75" (3-100mm)

Length: 2m, 2.5m, 3m (maximum length of 6m, customizable for cutting)

Standards: DIN EN 754, ASTM B211, QQ-A-225/9

6063 CF Aluminum Rod Bar is a low-alloy Al-Mg-Si high-plasticity alloy rod with excellent characteristics such as heat-treatable reinforcement, high thermoplasticity, good weldability, and corrosion resistance. It is suitable for high-speed extrusion to create complex structures and can be used in the manufacturing of thin-walled, hollow profiles, or components with complex structures, such as electric tools, screw machines, gears, and fittings. Its smooth surface facilitates anodizing and dyeing. However, allowing it to age after quenching may adversely affect its strength.

Straightness and Tolerances of 6063 Precision Cold Drawing Aluminum Rod

| Diameter Tolerance | Straightness | True Roundness |

| -0.03mm | 0.3mm/m | 0.01mm |

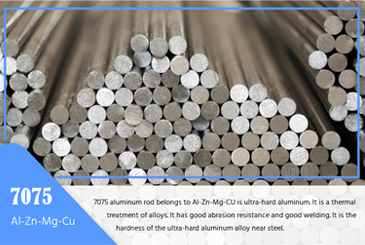

7075 Cold Drawn (CF) Aluminum Rod Bar

Temper: O, F, T6, T651, T7351

Diameter: 0.125 "-3.75" (3-100mm)

Length: 2m, 2.5m, 3m (maximum length of 6m, customizable for cutting)

Standards: DIN EN 754, ASTM B211, QQ-A-225/9, AMS 4122, AMS 4123, AMS 4124, AMS 4186, AMS 4187

7075 CF Aluminum Rod Bar is one of the strongest and hardest alloys available, featuring excellent machinability, good corrosion resistance, and fine grain control. As one of the highest-strength aluminum alloys, it finds widespread applications in aerospace, firearms, and other high-stress applications.

7075 Cold Drawn (CF) Aluminum Rod Bar, known for its superior strength-to-weight ratio and corrosion resistance, is particularly suitable for manufacturing lightweight yet durable components. This includes aircraft rivets, automotive parts, tent stakes, climbing safety carabiners, and more.

Straightness and Tolerances of 7075 Precision Cold Drawing Aluminum Rod

| Diameter Tolerance | Straightness | True Roundness |

| -0.03mm | 0.3mm/m | 0.01mm |

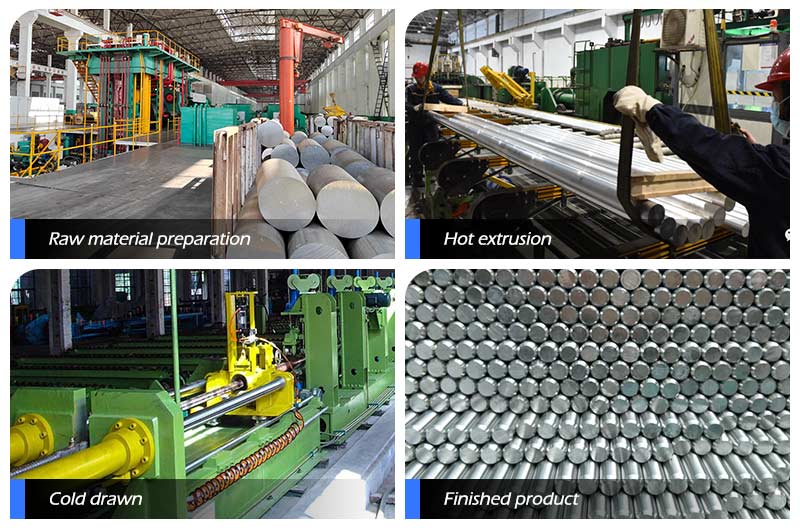

Production process of precision cold drawing aluminum rod bar

- Raw Material Preparation: Select high-purity aluminum rod blanks to ensure they meet production standards and customer requirements.

- Extrusion: Use an extrusion machine to extrude the pre-treated aluminum rod blanks into a preliminary round cross-section. Extrusion helps improve the grain structure of the blanks, enhancing mechanical performance.

- Drawing: Continue to draw the aluminum rods to further enhance strength and hardness.

- Cold Drawing: Gradually reduce the temperature and stretch the extruded aluminum round bars using a cold drawing machine to decrease the diameter.

- Multiple Drawing Passes: Subject the cold-drawn aluminum rods to multiple drawing passes to further reduce the diameter, improving product density and strength.

- Straightening: Straighten the drawn aluminum rods to ensure their straightness and length meet standard requirements.

- Chamfering: Apply chamfering treatment to the aluminum rods, making them suitable for automatic feeding during machining without material jamming.

- Heat Treatment: Subject the precision-machined aluminum rods to heat treatment, including heating and cooling processes, to adjust the alloy's crystal structure and enhance strength and hardness.

- Quality Inspection: Conduct comprehensive quality checks, including tolerance, diameter, roundness, etc., to ensure the products meet relevant standards and technical requirements.

- Packaging and Shipment: Package the qualified precision cold-drawn aluminum rods securely to prevent damage during transportation and deliver them to the customer.

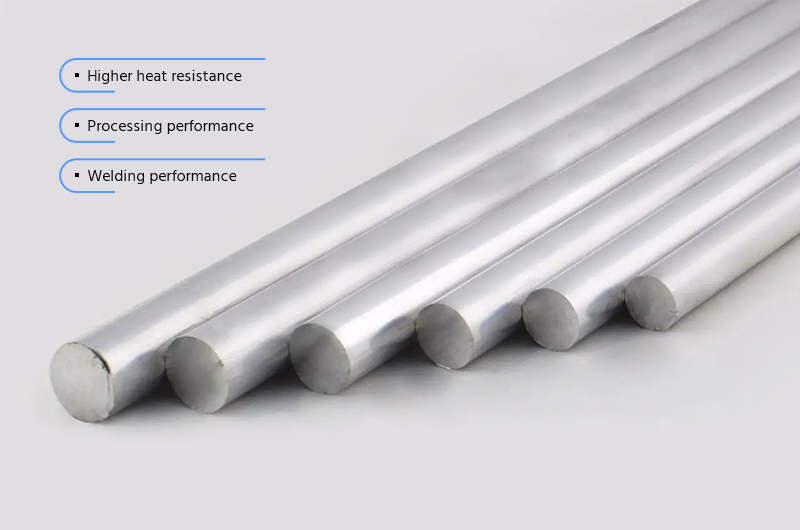

Advantages of precision cold drawing aluminum rod bar

- Superior Mechanical Performance: Manufactured with high-quality alloys, it exhibits outstanding mechanical machining capabilities, ensuring product quality.

- Relatively High Precision: Small diameter tolerances, excellent straightness, and true roundness, along with high material consistency, guarantee high-precision standards for the product.

- Improved Surface Smoothness: Enhances both quality and aesthetics while reducing the need for additional surface processing, providing customers with more attractive finished products.

- Suitable for High-Speed Spindles: Ideal for use in CNC machines with spindle speeds above 5000, supporting high-speed spindle operation to enhance production efficiency.

- Enhanced Straightness Capability: Automated bar feeding improves production efficiency, reduces manual intervention, and minimizes the possibility of human errors.

- Increased Production Efficiency: Superior straightness supports high-speed spindle operation, effectively improving production efficiency, reducing equipment damage, and extending equipment lifespan.

- Advantage in Automated Production: Chamfering at both ends facilitates automatic feeding, preventing material jamming and increasing operational efficiency, ensuring high-quality finished products.

- Cost-Effective: Saves on material and labor costs, reduces waste and rework, enhances material yield, resulting in better cost-effectiveness.

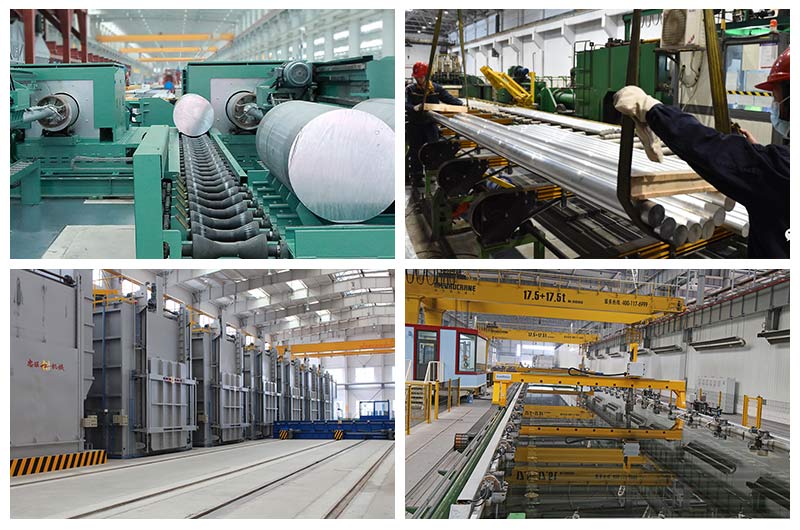

Precision Drawn Aluminum Rod Supplier - Chalco

- Comprehensive Product Range: Chalco provides a full range of aluminum products, including extruded aluminum bars and precision drawn aluminum bars, to meet diverse needs.

- Advanced Production Equipment: Equipped with advanced 12, 500-ton dual-action reverse extrusion production lines, highly stable drawing production lines, a 6, 000-ton stretch straightening machine, multiple imported cutting machines, fully automatic feeding saws, vertical large-scale automatic feeding machines, and other processing equipment.

- Complete Molds: Chalco possesses hundreds of molds, and most popular sizes can be directly matched, saving on customized mold costs and time, and flexibly meeting the needs of most customers.

- Precision Machining Services: Offers various precision machining services such as fixed-length cutting, precision grinding, precision turning, straightening, bending, and machining, catering to individualized requirements.

- Quality and Certifications: Chalco has obtained certifications including AS9100, OHSAS 18001, ISO 14001, ISO 9001, NADCAP HT, NADCAP NDT, IATP16949, ensuring that products meet high-quality standards.

Precision drawing(CF)aluminum bar vs. Precision ground aluminum rod

Difference in Accuracy

- Precision drawing(CF)aluminum bar: Utilizes drawing processes, Accuracy can achieve outer diameter tolerance of -0.03, true roundness <0.01mm, straightness <0.3mm/m.

- Precision Ground Aluminum Rod: Utilizes grinding processes, Accuracy can achieve outer diameter tolerance of -0.02, true roundness <0.005mm, straightness <0.2mm/m.

Difference in Production Process

- Precision drawing(CF)aluminum bar: Drawing process involves stretching aluminum rod blanks multiple times, gradually reducing the cross-sectional area to form the desired diameter.

- Precision Ground Aluminum Rod: Grinding process using grinding wheels or grinding machines to achieve specified diameter, tolerance, and surface smoothness.

Difference in Surface Treatment

- Precision drawing(CF) aluminum bar: Higher surface smoothness due to the characteristics of the drawing process, often eliminating the need for additional grinding steps.

- Precision Ground Aluminum Rod: Further improves surface smoothness through grinding processes.Minimum roughness after fine polishing can reach Ra0.1, suitable for direct use in appearance parts.

Difference in Production Speed and Cost

- Precision drawing (CF) aluminum bar: Typically faster production speed, allowing for efficient mass production at lower costs.

- Precision Ground Aluminum Rod: Slower production speed due to additional grinding steps, resulting in relatively higher costs.

Difference in Applications and Characteristics

- Precision drawing (CF) aluminum bar: Used in applications with high surface smoothness requirements but relatively lower demands on diameter accuracy.Applications include some mechanical components, automotive engine parts, tent pegs, aircraft rivets, etc.

- Precision Ground Aluminum Rod: Suitable for applications with high demands on diameter tolerance, straightness, and surface smoothness.Applications include precision instrument manufacturing, coreless machines, medical stethoscopes, surgical clamp, climbing safety buckles, etc.

Product list of Precision drawing(CF) aluminum bar

| l Cold Finished Aluminum Rod Bar | l Precision Cold Finished Aluminum Rod |

| l Cold Polished Finished Aluminium Bar | l Precision cold drawn aluminum bar |

| l Cold Treatment Aluminum Bar Billet | l Cold Roll Aluminum Round Bar |

| l Cold Drawn Round Aluminium Rod | l Turned Ground & Polished Bar |

| l Aluminium Rod Cold Drawn Bar Billets | l Cold Rolled Annealed Round Bar |

| l Aluminium Alloy Cold Drawn Round Bar | l Aluminum Solid Round Bar |

| l 2011-T8 Cold Drawn Aluminium Bar | l Cold Finish Aluminum Solid Round Bar |

| l Cold Finished Aluminum Rod Bar | l Precision Cold Finished Aluminum Rod |