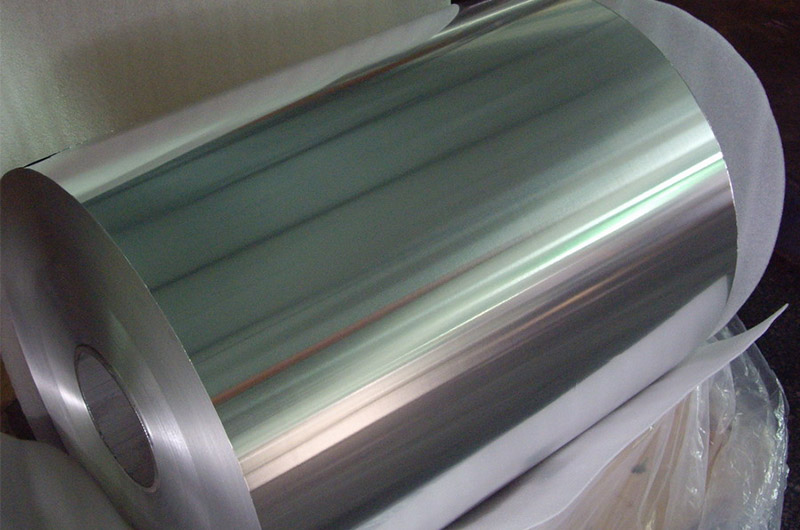

What is aluminum foil?

Aluminum foil is a very thin aluminum product, usually less than 0.2 mm thick. It is made of high-purity aluminum metal and contains about 92-99% aluminum and can be easily bent or torn. The width and strength of aluminum foil will vary greatly for different applications. It is a durable, non-toxic, oil-proof and chemical-resistant material.

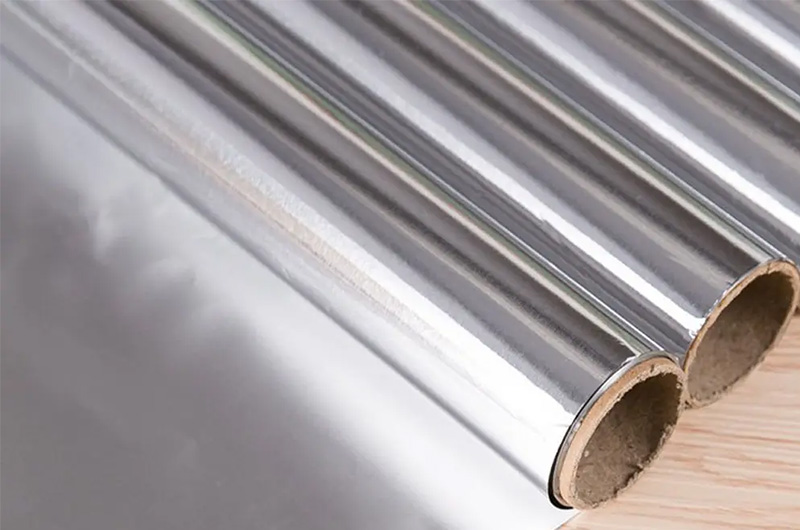

What is tin foil?

Tin foil is a thin and soft metal foil material mainly made of tin. The thickness usually ranges from 0.006mm to 0.2mm. It has the characteristics of good electrical and thermal conductivity, low melting point and strong plasticity. It can be widely used in electronic circuit welding, food Packaging, making tinfoil, capacitor electrodes, cooking utensils, jewelry and sculpture creation and other fields.

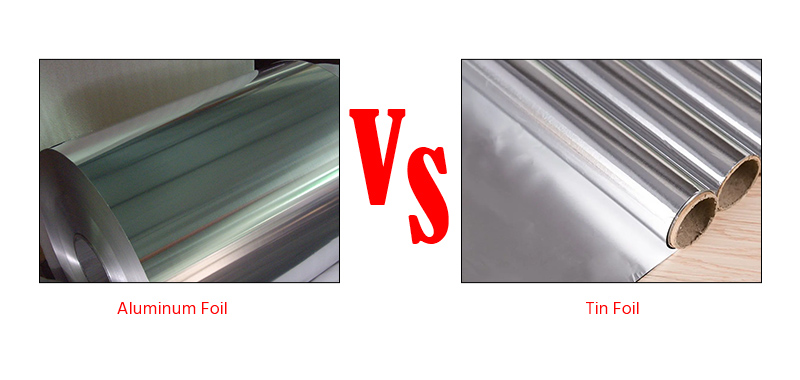

Appearance of aluminum foil and tin foil

Aluminum foil and tin foil are very similar in appearance, but there are some obvious differences that help us tell them apart. The first is the color. Aluminum foil is silver-white, while tin foil and aluminum foil are similar in color, but tin foil is much brighter than aluminum foil. Second is the texture. Aluminum foil is relatively hard, with a thickness generally between 0.006-0.2 mm. Tin foil is relatively soft, with a thickness generally between 0.006 and 0.2 mm. Between 0.009-0.05 mm, you can easily feel the difference by touching it with your hands.

Melting points of aluminum foil and tin foil

The melting point of aluminum foil is 660°C and the boiling point is 2327°C. The melting point of tin foil is 232°C and the boiling point is 2260°C. Therefore, aluminum foil is usually preferred over tin foil in environments with higher temperatures such as grilling, cooking, and air frying.

Ductility of aluminum foil and tin foil

Aluminum foil has very good ductility, and tin foil also has certain ductility. However, compared with aluminum foil, the ductility of tin foil is still much worse. The fundamental reason for these differences is the difference in material composition, material crystal structure and processing method.

Thermal conductivity of aluminum foil and tin foil

The thermal conductivity of aluminum is 237 W/mK, and that of tin is only 66.6 W/mK, so the thermal conductivity of aluminum foil is much better than that of tin foil. Due to its high thermal conductivity, aluminum foil is often used in cooking, for example, to wrap food to promote even heating and grilling, and to make heat sinks to facilitate rapid heat conduction and cooling.

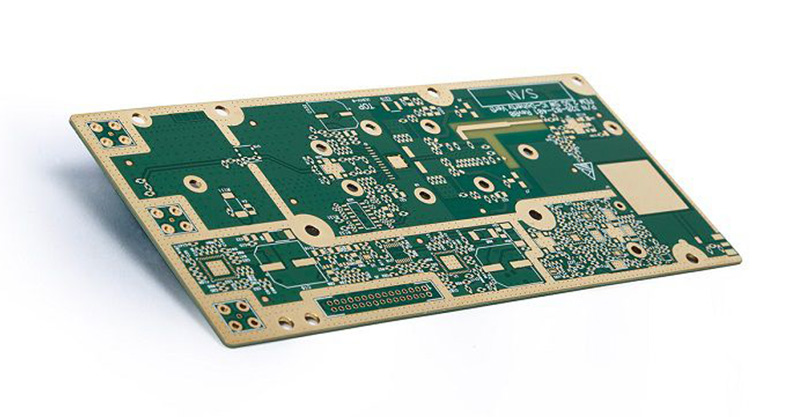

Conductivity of aluminum foil and tin foil

The resistivity of aluminum is about 2.82×10^-8 Ω·m, while the resistivity of tin is about 11.5×10^-8 Ω·m, which is much larger than aluminum, so under the same conditions, the conductivity of aluminum foil is better than Tinfoil is much better. Therefore, aluminum foil is particularly suitable for the production of high-frequency precision circuit boards and capacitor foil materials in high-power circuits, while tin foil is suitable for internal connections of electronic equipment that does not require high conductivity but requires a certain degree of ductility.

Aluminum foil and tin foil prices

The price of tin foil is usually higher than that of aluminum foil, mainly because tin is more expensive as a raw material and its manufacturing process is relatively complex. Due to the advantages of aluminum resources and mature processing technology, the price of aluminum foil is generally lower than that of tin foil, which is one of the reasons why aluminum foil is more popular.

Food packaging

Aluminum foil and tin foil both have good air tightness, anti-corrosion and non-stick properties and are widely used in the field of food packaging, but there are still some differences between the two. If the food wrapped in tin foil is left for too long, it will leave a bitter taste and affect the taste, while aluminum foil packaging is relatively stable and will not produce odor. This is also the main reason why most food packaging now chooses aluminum foil.

Recycling and reuse

Aluminum foil can be reused after cleaning, and due to the complete and mature process, the recycling of aluminum foil is simpler, and the recycling rate can reach more than 75%. The recycling of tin foil involves purification from the material. The process is relatively complex and the recycling cost is high. The recycling rate is about 25-45%.