Brazing composite foil for automobiles is mainly used in pipelines, joints and connecting parts of automobile radiators to achieve efficient heat conduction and heat dissipation. It is able to withstand the high temperatures and pressures of automotive engines and other heat sources while providing a reliable connection.

Why choose Chalco brazed composite aluminum foil for automobiles?

Chalco Aluminum has passed the requirements of the automotive IATF16949 standard audited by BSI (British Standards Institution), providing quality compliance for continuously expanding the automotive product market and achieving high-quality development.

Chalco Aluminum serves Tesla, Ford, Shanghai Automobile, Weilai Automobile, Beiqi New Energy, Changan Automobile and other famous new energy automobile manufacturers. Some models of automotive plate material certification.

Specifications of composite aluminum foil for automotive fins

| Alloy | Temper | Thickness mm | |

| Brazing layer | Substrate | ||

| 4A13, 4A17, 4A43, 4A45, 4004, 4045, 4104, 4343 | 3A11, 3003, 7A11 | H14 | 0.050-0.200 |

| H16 | 0.050-0.200 | ||

For automotive brazing clad aluminum foil, the common width range is usually between 100mm and 1000mm. The exact width depends on the design requirements of the automotive component, the dimensions of the connecting pipes, and the manufacturer's specifications.

For the composite aluminum foil used for automotive fins, the width range is usually determined according to the design of the radiator and the size of the fins to meet the heat dissipation performance requirements of the radiator. The width can be customized according to specific design requirements, usually between a few millimeters and tens of millimeters.

| Coverage /% | Allowable deviation of cladding ratio of composite foil/% | |

| Normal level | High precision level | |

| 5-6 | ±2.0 | ±1.0 |

| >6-8 | ±2.5 | ±1.5 |

| >8-13 | ±3.0 | ±2.0 |

| >13-20 | ±4.0 | ±3.0 |

| Composite foil width deviation | |

| Width | Width tolerance |

| 7.0-100.0 | ±0.1 |

| >100.0-300.0 | ±0.3 |

| >300.0-1 320.0 | ±1.0 |

Mechanical properties of composite aluminum foil for automotive fins

| Alloy | Temper | Thickness mm | Tensile strength Rm N/mm2 | Specified non-proportional extension strength R p0.2 N/ mm2 | Elongation after breaking A50mm% | |

| Brazing layer | Substrate | Not less than | ||||

| 4A13, 4A17, 4A43, 4A45, 4004, 4045, 4104, 4343 | 3A11, 3003, 7A11 | H14 | 0.050-0.100 | 150-210 | 135 | 0.5 |

| >0.100-0.200 | 1.0 | |||||

| H16 | 0.050-0.100 | 170-230 | 160 | 0.5 | ||

| >0.100-0.200 | 1.0 | |||||

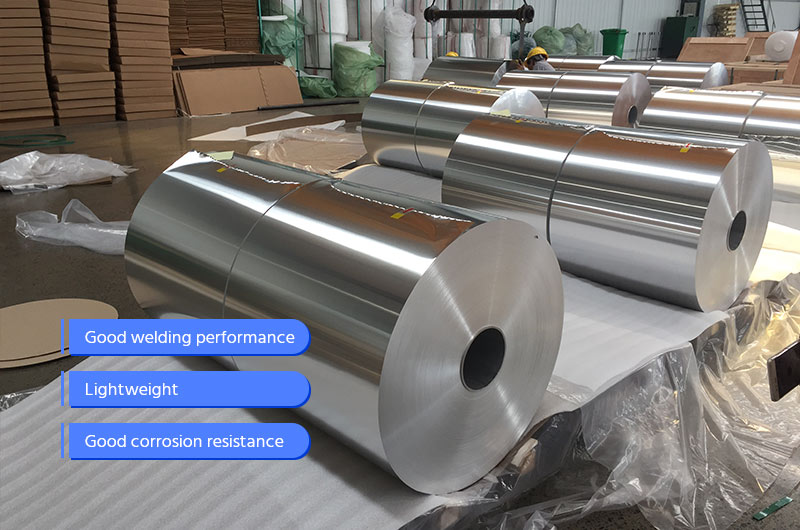

Properties of automotive brazing composite aluminum foil

Good welding performance

Auto brazing composite aluminum foil can be reliably connected with other metal parts through brazing process to ensure the tightness and strength of the connection point.

Excellent thermal conductivity

Brazed composite aluminum foil usually uses aluminum alloy with high thermal conductivity as the base material, which can quickly transfer heat and improve heat exchange efficiency.

Lightweight

As the main material, aluminum alloy has a low density, which can reduce the weight of the entire auto parts and improve the fuel efficiency and performance of the vehicle.

Good corrosion resistance

Aluminum alloy has good corrosion resistance, can resist common corrosive media, and prolong the service life of the product.

High strength and rigidity

The structural design of the brazed composite aluminum foil makes it have high strength and rigidity, and can remain stable under vibration, impact and other external forces.

Plasticity and formability

Brazed composite aluminum foil has good plasticity and formability, and can be processed and formed according to needs to meet the requirements of various complex shapes and sizes.

It should be noted that the specific performance characteristics will vary with different alloy grades, processing conditions and manufacturing processes. When selecting and applying automotive brazing composite aluminum foil, appropriate materials and specifications should be selected according to specific product requirements, design requirements and application environments to ensure that performance and reliability requirements are met.

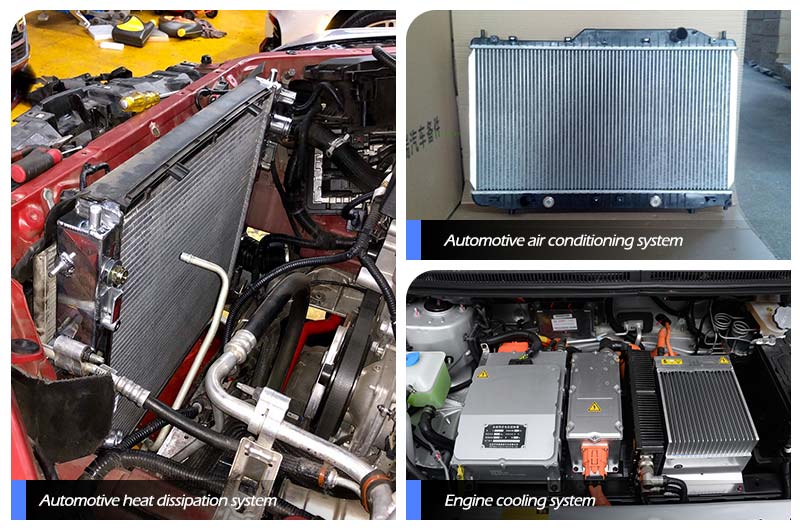

The use of brazing composite aluminum foil for automobiles in the field of automobiles

Brazing composite aluminum foil for automobiles is widely used in the field of automobiles, mainly for the following aspects.

Radiator and cooling system: brazed composite aluminum foil is often used for fins and pipes in automotive radiators and cooling systems. They can be connected with other metal parts (such as copper pipes) by brazing technology, providing excellent thermal conductivity, effective heat dissipation and lower temperature.

Air-conditioning system: brazed composite aluminum foil is used for fins and condensers of automotive air-conditioning systems. The fins are used to increase the heat exchange surface area and improve the cooling effect; the condenser is used to cool the high-temperature and high-pressure gas discharged from the compressor into liquid.

Exhaust system: brazed composite aluminum foil is widely used in catalytic converters and exhaust pipes in automobile exhaust systems. They are able to withstand high temperatures and corrosive environments while providing good thermal conductivity and structural strength.

Energy saving and emission reduction system: brazed composite aluminum foil plays an important role in the energy saving and emission reduction system of automobiles. For example, in the battery cooling system of hybrid vehicles, brazed composite foil can be used to enhance the cooling effect and ensure the stable operation of the battery.

Other applications: brazed composite aluminum foil for automobiles can also be used for thermal management and structural connection of multiple automotive components such as turbochargers, fuel cell systems, battery cooling systems for electric vehicles, and transmission systems.

By using brazed clad aluminum foil, automakers can improve thermal management efficiency, reduce energy consumption, reduce size and weight, and improve vehicle performance and reliability.

Key points for purchasing brazed composite aluminum foil for automobiles

Material quality

Make sure to select a quality material supplier or manufacturer. The brazed composite aluminum foil produced by Chalco Aluminum adopts strict quality and environmental management system to ensure that it complies with ISO 9001 and ISO 14001 certification, IATF16949 certification, etc., and can meet your application needs.

Alloy grade and specification

Select the appropriate alloy grade and specification according to specific application requirements. The most suitable material is selected considering the required strength, thermal conductivity, corrosion resistance, etc. requirements.

Supply chain reliability

select reputable and reliable suppliers to ensure timely and continuous supply. Chalco Aluminum is a supplier with a good reputation and perfect after-sales service to ensure your purchasing experience is pleasant and smooth.

Price and cost performance

Considering the balance between price and performance, choose a reasonable price and cost performance. Chalco Aluminum is affordable and widely favored by auto parts manufacturers.

Technical support and after-sales service

Chalco Aluminum is a supplier and material manufacturer that can provide good technical support and after-sales service, so as to ensure that customers can get timely help and support in the process of purchasing and using.

Delivery time and packaging

Ensure that suppliers can deliver on time and take appropriate packaging measures to ensure product integrity and safe transportation.

Sustainability considerations

consider the selection of environmentally friendly materials and suppliers to meet the requirements of sustainable development. Learn about suppliers' environmental protection policies and related certifications.

To sum up, the purchase of brazed composite aluminum foil for automotive needs to comprehensively consider material quality, alloy grade, supply chain reliability, certification and quality assurance, price and cost performance, technical support, delivery time and packaging, and sustainability, etc. to ensure that the purchased product meets requirements and has good performance and reliability.