2090 aluminum alloy is a high-strength, high-corrosion-resistant aluminum alloy material, which is suitable for the manufacture of components that require high material strength and corrosion resistance in the aerospace field.

AMS 4232 2090-T86 Extrusion aluminum profiles are widely used in the manufacture of structural parts, shells, frames, screws, bolts and other components in the aerospace field, and are also suitable for other fields that require high strength and corrosion resistance.

Why choose Chalco 2090 aviation aluminum profile?

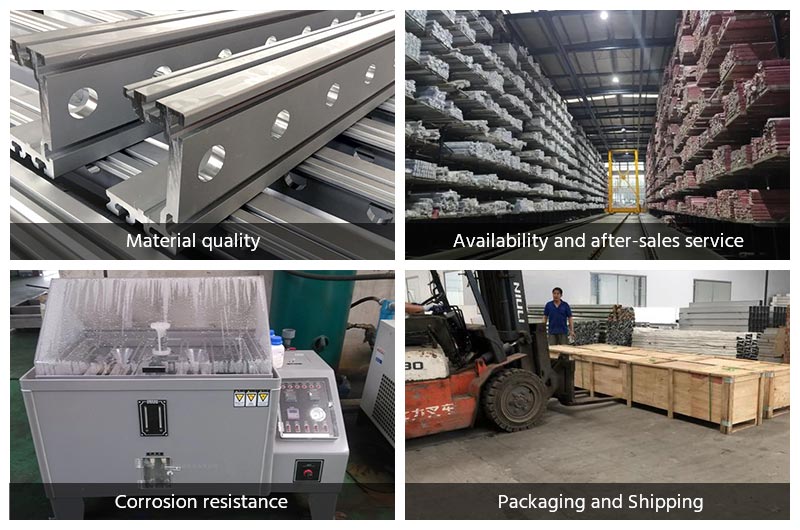

Chalco Aluminum provides excellent quality aerospace materials, as well as the best technical services in the market, and has a deep knowledge base on how to support customers in meeting the challenges of the future.

Standard

A97050,

AMS 4344,

AMS 4341,

AMS 4232 etc.

We have passed AS9100, OHSAS 18001 and other certifications required by the aviation industry, providing a strong guarantee for the quality of aerospace materials produced by our company.

Accreditations

AS9100

OHSAS 18001

ISO14001

ISO9001

NADCAP HT

NADCAP NDT

IATP16949

Chemical composition 2090 aluminum profile

| Element | Minimum | Maximum |

| Copper | 4.30 | 4.90 |

| Magnesium | 1.20 | 1.60 |

| Iron | 0.12 | 0.20 |

| Silicon | 0.10 | 0.40 |

| Manganese | 0.30 | 0.60 |

| Chromium | 0.23 | 0.35 |

| Zinc | 0.25 | 0.40 |

| Titanium | 0.05 | 0.20 |

| Other | 0.15 | |

| Aluminum | Balance | Balance |

Physical properties of 2090 aluminum profile

| Property | Value |

| Density | 2.85 g/cm3 |

| Elastic modulus | 72 GPa |

| Poisson's ratio | 0.33 |

| Thermal expansion coefficient | 23.1 μm/m-°C |

| Thermal conductivity | 154 W/m-°C |

| Electrical conductivity | 31.7 MS/m |

The performance list T6 and T86 of 2090 aluminum alloy profiles

| Performance parameters | T6 Temper | T86 Temper |

| Strength | About 400 MPa | About 390 MPa |

| Yield strength | About 360 MPa | About 360 MPa |

| Elongation | About 6% | About 5% |

| Hardness | About 110 HB | About 105 HB |

| Creep resistance | Excellent | - |

| Stress corrosion cracking resistance | - | Excellent |

| Fracture toughness | - | Good |

Application of 2090 aluminum alloy in aviation field

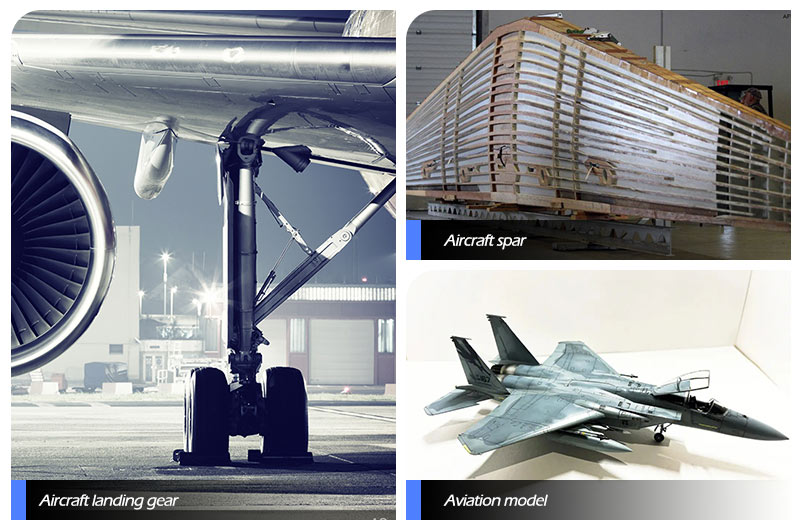

Aircraft structure: 2090 aluminum alloy profiles can be used to manufacture various parts in aircraft structures, such as fuselage, wings, beams, etc. Its high strength and lightweight characteristics make the overall weight of the aircraft lighter, which can improve flight speed and fuel efficiency.

Aviation components: 2090 aluminum alloy profiles can be used to manufacture aviation components, such as engine casings, air intakes, landing gear, etc. Its high strength and corrosion resistance can ensure the safety and reliability of these parts during flight.

Aviation model: 2090 aluminum alloy profiles can be used to manufacture various aviation models, such as simulated airplanes, rockets, etc. Its high strength and good processing performance can ensure the structural strength and appearance quality of the model.

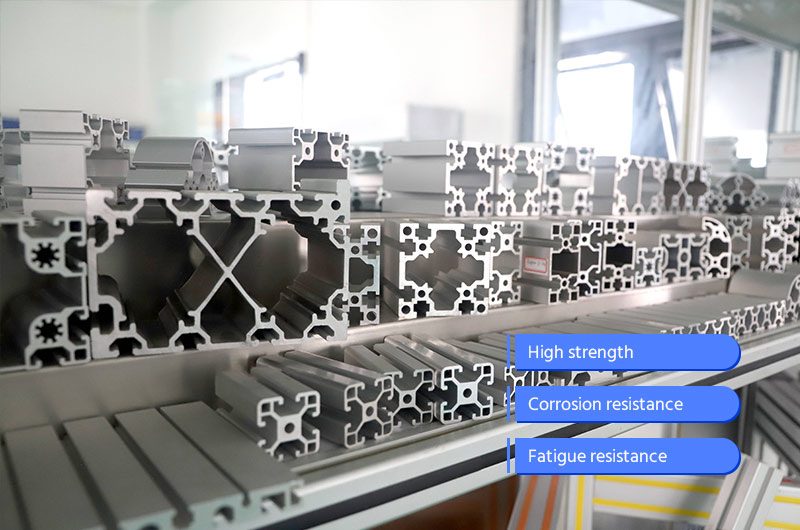

Characteristics of 2090 aluminum alloy profiles

High strength: 2090 aluminum alloy profiles have excellent strength and toughness, and their strength is more than 20% higher than conventional aluminum alloy profiles, which can withstand high-strength and high-stress environments.

Lightweight: 2090 aluminum alloy profiles have a lower density, so they are lighter than steel and other metal materials, which helps to reduce the weight of the entire equipment or component.

Corrosion resistance: 2090 aluminum alloy profile has good corrosion resistance and is not easy to rust, which helps to reduce the maintenance cost of equipment or components and prolongs the service life.

Machinability: 2090 aluminum alloy profiles have good machinability, are easy to process into various shapes and sizes, and are helpful for the manufacture of components with complex structures.

Fatigue resistance: 2090 aluminum alloy profiles have excellent fatigue resistance and can withstand long-term high-frequency use and repeated stress cycles.

Good thermal conductivity and electrical conductivity: 2090 aluminum alloy profiles have good thermal conductivity and electrical conductivity, and can be widely used in occasions that require heat dissipation and electrical conductivity.

Precautions when using 2090 aluminum alloy profiles

Avoid mechanical damage: 2090 aluminum alloy profiles have high strength and toughness, but still need to avoid mechanical damage. During transportation, storage and processing, care should be taken to avoid damage such as impact, extrusion and scratches, so as to ensure the integrity and use effect of the profile.

Avoid chemical corrosion: 2090 aluminum alloy profiles have good corrosion resistance, but it is still necessary to avoid prolonged contact with chemical substances containing acids, alkalis or chloride ions to avoid corrosion.

Reasonable use temperature: the use temperature range of 2090 aluminum alloy profiles should be determined according to specific conditions. In high temperature or low temperature environment, care should be taken to protect the surface of the profile to avoid affecting its performance.

Reasonable storage and protection: 2090 aluminum alloy profiles should be stored in a dry, ventilated, dust-free, acid-free and alkali-free environment. During transportation and storage, avoid moisture, heat, direct sunlight and mechanical damage.

Pay attention to the surface treatment of profiles: 2090 aluminum alloy profiles can be treated by sandblasting, anodizing, electrophoretic coating and other surface treatments to enhance their corrosion resistance, wear resistance and decoration. However, different surface treatment methods have different effects on its performance, and the appropriate surface treatment method should be selected according to the specific situation.

When purchasing 2090 aluminum alloy profiles, you need to pay attention to the following items

Specifications and sizes: choose the appropriate specifications and sizes to meet specific usage needs. You can refer to relevant standards or technical data as needed, or consult manufacturers or suppliers.

Quality and certification: choose reputable and qualified manufacturers or suppliers to ensure that the quality and performance of products meet the requirements. At the same time, suppliers are required to provide relevant certification documents and quality assurance certificates.

Price and delivery time: on the basis of considering product quality and performance, select suppliers with reasonable price and short delivery time. You can compare the prices and delivery dates of several suppliers to choose the most suitable one.

Packaging and Shipping: choose a supplier with good packaging and reliable shipping to ensure that the product is not damaged during shipping. Before purchasing, you can ask the supplier to provide relevant packaging and transportation solutions, etc.

After-sales service: choose a supplier with good after-sales service, so that you can solve problems in time when you encounter problems during use. You can learn about the supplier's after-sales service commitment and service capabilities, etc., to choose the most suitable supplier.