6063 aluminum bars belong to low-alloy Al-Mg-Si series high plasticity alloys, known for their excellent surface finish, with excellent extrusion performance, good corrosion resistance and comprehensive mechanical properties, and are susceptible to oxidization discoloration.

The alloy is used for standard architectural shapes, custom solids and heat sinks. Due to its conductivity, it can also be used for electrical applications of T5, T52 and T6 tempers.

| Description | Diameter |

| 6063 T6 Dia 3mm alu rod | 3mm |

| 6063 T6 Dia 1/8'' alu rod | 1/8'' |

| 6063 T6 Dia 5/32'' alu rod | 5/32'' |

| 6063 T6 Dia 4mm alu rod | 4mm |

| 6063 T6 Dia 3/16'' alu rod | 3/16'' |

| 6063 T6 Dia 5mm alu rod | 5mm |

| 6063 T6 Dia 7/32'' alu rod | 7/32'' |

| 6063 T6 Dia 6mm alu rod | 6mm |

| 6063 T6 Dia 1/4'' alu rod | 1/4'' |

| 6063 T6 Dia 7mm alu rod | 7mm |

| 6063 T6 Dia 5/16'' alu rod | 5/16'' |

| 6063 T6 Dia 8mm alu rod | 8mm |

| 6063 T6 Dia 9mm alu rod | 9mm |

| 6063 T6 Dia 3/8'' alu rod | 3/8'' |

| 6063 T6 Dia 10mm alu rod | 10mm |

| 6063 T6 Dia 11mm alu rod | 11mm |

| 6063 T6 Dia 7/16'' alu rod | 7/16'' |

| 6063 T6 Dia 12mm alu rod | 12mm |

| 6063 T6 Dia 1/2'' alu rod | 1/2'' |

| 6063 T6 Dia 13mm alu rod | 13mm |

| 6063 T6 Dia 14mm alu rod | 14mm |

| 6063 T6 Dia 9/16'' alu rod | 9/16'' |

| 6063 T6 Dia 15mm alu rod | 15mm |

| 6063 T6 Dia 5/8'' alu rod | 5/8'' |

| 6063 T6 Dia 16mm alu rod | 16mm |

| 6063 T6 Dia 17mm alu rod | 17mm |

| 6063 T6 Dia 11/16'' alu rod | 11/16'' |

| 6063 T6 Dia 18mm alu rod | 18mm |

| 6063 T6 Dia 3/4'' alu rod | 3/4'' |

| 6063 T6 Dia 20mm alu rod | 20mm |

| 6063 T6 Dia 22mm alu rod | 22mm |

| 6063 T6 Dia 7/8'' alu rod | 7/8'' |

| 6063 T6 Dia 24mm alu rod | 24mm |

| 6063 T6 Dia 25mm alu rod | 25mm |

| 6063 T6 Dia 1'' alu rod | 1'' |

| 6063 T6 Dia 26mm alu rod | 26mm |

| 6063 T6 Dia 27mm alu rod | 27mm |

| 6063 T6 Dia 1 1/8'' alu rod | 1 1/8'' |

| 6063 T6 Dia 30mm alu rod | 30mm |

| 6063 T6 Dia 1 1/4'' alu rod | 1 1/4'' |

| 6063 T6 Dia 32mm alu rod | 32mm |

| 6063 T6 Dia 1 3/8'' alu rod | 1 3/8'' |

| 6063 T6 Dia 35mm alu rod | 35mm |

| 6063 T6 Dia 36mm alu rod | 36mm |

| 6063 T6 Dia 38mm alu rod | 38mm |

| 6063 T6 Dia 1 1/2'' alu rod | 1 1/2'' |

| 6063 T6 Dia 40mm alu rod | 40mm |

| 6063 T6 Dia 1 5/8'' alu rod | 1 5/8'' |

| 6063 T6 Dia 1 3/4'' alu rod | 1 3/4'' |

| 6063 T6 Dia 45mm alu rod | 45mm |

| 6063 T6 Dia 1 7/8'' alu rod | 1 7/8'' |

| 6063 T6 Dia 48mm alu rod | 48mm |

| 6063 T6 Dia 50mm alu rod | 50mm |

| 6063 T6 Dia 2'' alu rod | 2'' |

| 6063 T6 Dia 2 1/8'' alu rod | 2 1/8'' |

| 6063 T6 Dia 55mm alu rod | 55mm |

| 6063 T6 Dia 2 1/4'' alu rod | 2 1/4'' |

| 6063 T6 Dia 60mm alu rod | 60mm |

| 6063 T6 Dia 2 3/8'' alu rod | 2 3/8'' |

| 6063 T6 Dia 2 1/2'' alu rod | 2 1/2'' |

| 6063 T6 Dia 65mm alu rod | 65mm |

| 6063 T6 Dia 2 5/8'' alu rod | 2 5/8'' |

| 6063 T6 Dia 2 3/4'' alu rod | 2 3/4'' |

| 6063 T6 Dia 70mm alu rod | 70mm |

| 6063 T6 Dia 3'' alu rod | 3'' |

| 6063 T6 Dia 80mm alu rod | 80mm |

| 6063 T6 Dia 3 1/4'' alu rod | 3 1/4'' |

| 6063 T6 Dia 85mm alu rod | 85mm |

| 6063 T6 Dia 3 1/2'' alu rod | 3 1/2'' |

| 6063 T6 Dia 95mm alu rod | 95mm |

| 6063 T6 Dia 3 3/4'' alu rod | 3 3/4'' |

| 6063 T6 Dia 4'' alu rod | 4'' |

| 6063 T6 Dia 105mm alu rod | 105mm |

| 6063 T6 Dia 4 1/4'' alu rod | 4 1/4'' |

| 6063 T6 Dia 110mm alu rod | 110mm |

| 6063 T6 Dia 4 1/2'' alu rod | 4 1/2'' |

| 6063 T6 Dia 115mm alu rod | 115mm |

| 6063 T6 Dia 120mm alu rod | 120mm |

| 6063 T6 Dia 4 3/4'' alu rod | 4 3/4'' |

| 6063 T6 Dia 5'' alu rod | 5'' |

| 6063 T6 Dia 5 1/2'' alu rod | 5 1/2'' |

| 6063 T6 Dia 150mm alu rod | 150mm |

| 6063 T6 Dia 6'' alu rod | 6'' |

| 6063 T6 Dia 155mm alu rod | 155mm |

| 6063 T6 Dia 160mm alu rod | 160mm |

| 6063 T6 Dia 6 1/2'' alu rod | 6 1/2'' |

| 6063 T6 Dia 7'' alu rod | 7'' |

| 6063 T6 Dia 7 1/2'' alu rod | 7 1/2'' |

| 6063 T6 Dia 8'' alu rod | 8'' |

| 6063 T6 Dia 210mm alu rod | 210mm |

| 6063 T6 Dia 10'' alu rod | 10'' |

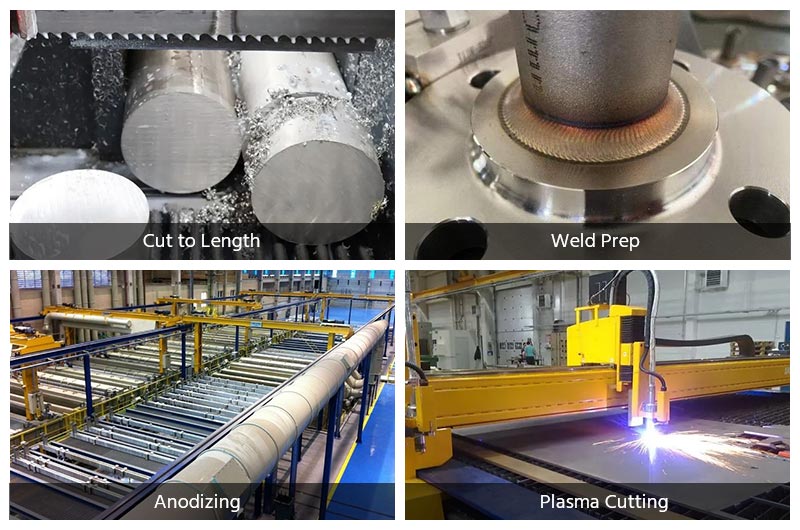

We provide services for 6063 aluminum rod

- Cut to Length

- Weld Prep

- Anodizing

- Oxidation discoloration

- Plasma Cutting

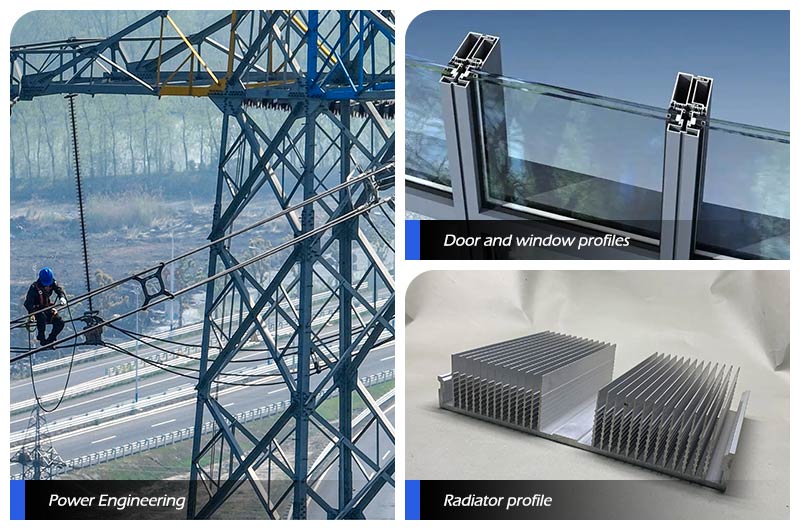

6063 aluminum bar application selection

Doors and windows profiles

Due to the excellent surface finish of 6063 aluminum round bars, they are widely used in building doors, windows and curtain wall profiles. They are typically extruded from F-temper aluminum die cast bars into T5, T6 and T66 tempers.

For general door and window applications, 6063-T5 aluminum alloy is usually sufficient. 6063-T6 or T66 aluminum alloys can be used if higher hardness is required, though they have higher cost.

Electrical applications

6063 has a standard electrical conductivity of 55-63% IACS and can be used for electrical applications in two forms. Aluminum busbar tubes can be extruded from aluminum round bars. Small diameter aluminum rods can also be used for conductive applications. Common tempers are T5, T6 and T52.

Electronics devices and heat sinks

Due to 6063 aluminum bars' good thermal conductivity and electrical conductivity, 6063 aluminum bars are often used to manufacture heat sinks, heat dissipation fins, electronic packaging and other products. Its corrosion resistance also makes 6063 aluminum bars an ideal material for marine electronic equipment.

Characteristics of 6063 aluminum rod

- Strengthened through heat treatment with high impact toughness and insensitive to notches.

- Excellent thermoplasticity, can be extruded at high speeds into complex structural shapes, thin-walled and hollow sections, or forged into complex structural forgings.

- Excellent weldability and corrosion resistance with no tendency to stress corrosion cracking. Among heat-treatable aluminum alloys, Al-Mg-Si alloys are the only alloys where stress corrosion cracking has not been observed.

- Processed surfaces are very smooth and readily anodized and colored.

6063 aluminum rod sizes and tolerance

- Dia. Tolerance:-0.002" to 0.002"

- Heat Treatment:Hardened

- Temperature Range, °F:-320° to 212°

- Straightness Tolerance:0.013" per ft.

Additionally, we also supply large diameter F temper 6063 aluminum die cast bars. If you have any requirements, please send your detailed needs to us at: sale@chalcoalumin.com.

6063 aluminum rod typical mechanical properties

| Temper | Tensile | Hardness | ||||

| Ultimate | Yield | Elongation | Brinell | |||

| KSI | MPA | KSI | MPA | % | ||

| T5, T52 | 27 | 186 | 21 | 145 | 12 | 60 |

| T6 | 35 | 241 | 31 | 214 | 12 | 73 |

Typical chemical composition

| Element | Composition % | |

| Si | 0.20-0.6 | |

| Fe | 0.35 | |

| Cu | 0.1 | |

| Mn | 0.1 | |

| Mg | 0.45-0.9 | |

| Cr | 0.1 | |

| Ni | - | |

| Zn | 0.1 | |

| Ti | 0.1 | |

| Other | Each | 0.05 |

| Total | 0.15 | |

| Al | Remainder | |

Effect and influence of Mg

Mg forms strengthening precipitates Mg2Si with Si. The higher the Mg content, the more Mg2Si precipitates form, giving greater strengthening response to heat treatment and higher tensile strength in extruded profiles.

However, resistance to deformation also increases with more Mg, reducing alloy ductility and worsening processability and corrosion resistance.

Effect and influence of Si

Si content should be sufficient for all Mg to be present as Mg2Si precipitates, ensuring the full effect of Mg is realized.

As Si content increases, the grain structure is refined, fluidity improves, castability becomes better, heat treatment response increases, tensile strength increases and ductility decreases in extruded profiles, and corrosion resistance worsens.。

You may be interested

-

6063 oil tank truck aluminum pipes are corrosion-resistant and have good processability

-

6063 T6 EC aluminum buspipe conforms to ASTM B241, ASTM B 317M-07, GB/T 33228-2016, etc.

-

6063 aviation aluminum flat bar according to QQ-A-200/9 and AMS 4156.

-

6063 O, T4 Automotive body structural parts, used in the manufacture of door frames, window frames, roof racks, trunks and other parts.