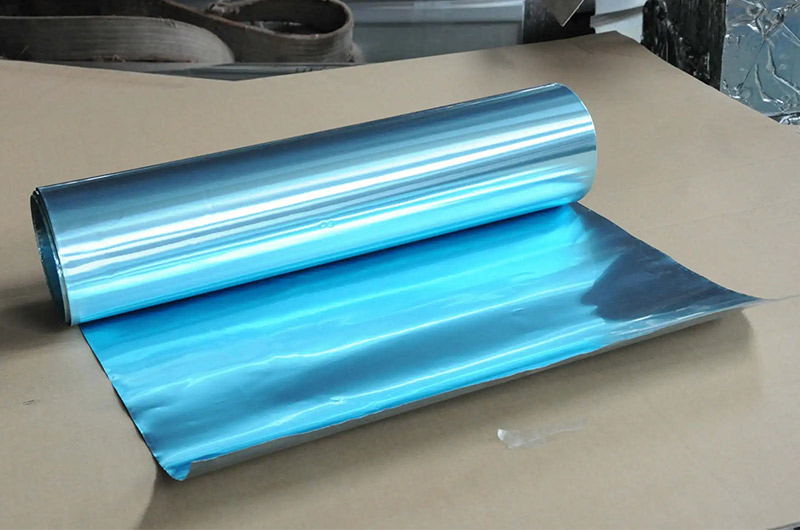

Color coated aluminum foil is an aluminum foil product whose surface is painted or coated. The performance of aluminum foil is so stable that the paint can last for several years without fading. The color coated aluminum foil can resist water, steam, light, taste, corrosion, heat and low temperature, and it is not easily affected by the environment and temperature. Therefore, it is often used in food, medicine, beverage, cosmetics, fragrance, etc., to prevent moisture absorption, oxidation, volatilization and deterioration of goods.

Common specifications of color coated aluminum foil products

| Equivalent name | aluminum paper, aluminum film, etc. |

| Metal alloy | 1000, 3000, 8000, etc. |

| Temper | soft O (HO) - H112 |

| Thickness | 0.015mm - 0.2mm |

| Width | 10mm - 1340mm |

| Inner diameter | 76mm / 152mm |

| Coating surface | single side, double side |

| standard | EN, AW, etc. |

| Authentication | SGS, etc. |

| Printing color |

gold, silver, red, blue, black, gray, white, green, copper, brown, wood, etc. can be customized according to customer requirements |

| Coating Products | heat sealing, printing primers, corrosion-resistant epoxies, demolding coatings, sliding lubricantsetc. |

| Thickness | 0.00035 inches to 0.020 inches |

| Slit widths range | 0.250 "to 56.50" |

| Super Thin Color Coated Aluminum Foil | The thinnest aluminum foil which could be coated is 0.015mm thickness for H Temper foil. The thinnest aluminum foil which could be coated is 0.04mm thickness for Soft O Temper foil. |

| Double Sides Color Coated Aluminum Foil, One-Time Production | Double rollers could produce color-coated foil on the front and back sides at the same time, increasing the production efficiency of double sides color-coated aluminum foil. |

| More Processing Technology To Meet Your Needs | We can reprocess color-coated aluminum foil, such as embossing, lacquering, lubricating, slitting and cutting, etc. |

| Rich Export Experience | With many years of export experience, it fully meets the needs of export packaging and can be packaged in suspended wooden cases |

| Support Sample And Small Batch Production | OEM & ODM Samples are available. |

Color coated aluminum foil coating products

Coated aluminum foil is used in applications that has a higher requirement for strength, protection, and aesthetics. Chalco provides various coating products:

Aluminum foil with LDPE coating

Camping mat, Thermal insulation for construction, Heat Lamination for Foam Insulations

PE coated aluminum foil

Heat insulation material, Protective Packaging Material

Epoxy paint coated aluminum foil

Food containers, semi-rigid containers and lids for the production of food packaging

PTFE coated aluminum foil

Covers for heat sealing jaws, bars, pads; covers for work stations and laboratory tables; linings for paint spray booths, ducts and conduits.

Carbon coated aluminum foil

Cathode Current Collector for Lithium-ion Batteries

Sliding lubricant

Sliding lubricant reduces friction and makes foil easier to use for die cutting or forming around another object.

Application field of color coated aluminum foil

Coated aluminum foil for containers

Chaclo' s color coated aluminum foil for food container is mainly used for food box, turkey plate, fish plate, fast food box, cake rack and aviation lunch box. The surface is coated with a layer of coating, which has good corrosion resistance, stamping performance and good appearance.Quick Quote

Because of its excellent thermal conductivity, it can reduce cooking time when used as food packaging. It is the Ideal material for cooling and heating. In addition, it can effectively block light, gas and pollutants, thus extending the storage time of food.

The aluminum cover made of color coated aluminum foil can ensure that food is kept in good condition at the best temperature for a longer time..

Specifications

| Alloy | 8011, 8006, 3003 and 3105 |

| Temper | H14 |

| Thickness | 0.04mm up to 0.1mm |

| Coating lacquer | Colorless or white lacquer on one side, and plain, colorless, white, coloured lacquered or printing on the other side, lubrication is optional. |

Coating properties

Epoxy based lacquers with excellent adhesion to aluminium foil (resistant to adhesive tape test) , good solvent resistance, good friction resistance and good resistance to dry heating (2 min./240℃). Different colours vailable on customer request. Thickness of coating depends on colour.

Coating color

| White lacquer | Polymerization > 50 double rubs/MECK |

| Coloured lacquer | Polymerization > 50 double rubs/MEK |

| Colourless lacquer | Polymerization> 35 double rubs/MEK |

Printing inks

Special inks developed for this application, resistant to heating and freezing.

Lubricant

Lubrication is optional. Quantity can be specified by the customer.

Features

Very good heat conductivity, that makes it suitable for freezing and re-heating.

Light weight that allows economizing on shortage and transport space.

Food can be heate by convection, fan or microwave oven.

Extraordinary properties for inlaying, with lacquers especially developed by our technical department for single inlay process as well as double inlay.

Coated aluminium foil for heat sealing cover

Chalco's color coated aluminum foil is used in the production of lids for the food market, providing unique advantages for this sector. The products preserve the freshness and good condition thanks to the properties of lacquered aluminium foil. They are safe for use in contact with foodstuff.

This kind of aluminum foil is mostly used to make the lid of dessert package, jam package, butter package, fresh cheese and other dairy products.

Specification

| Alloy | 8011, 8079 |

| Temper | O |

| Thickness | 0.03mm up to 0.05mm |

Coating Properties

Excellent adhesion to aluminium foil.

Water resistant (30 min at room temperature).

Resistant to heatsealing temperature. (max. 220℃ 1s)

Good printing results using nitrocellulosic inks and UV inks

Heatsealing lacquers

Heatsealing lacquer to PS/PVC:

Peel strength to PS> 5.5N/15mm. (180℃, 40kg, 1s)

Peel strength to PVC> 9N/15mm. (180℃, 40kg, 1s)

Heatsealing lacquer to PVC:

Peel strength to PVC> 9N/15mm. (180℃, 40kg, 1s)

Heatsealing lacquer to PP:

Peel strength to PVC> 9N/15mm. (200℃, 40kg, 1s)

Heatsealing lacquer to PE

Peel strength to PE> 9N/15mm. (200℃, 40kg, 1s)

Heatsealing lacquer to PP/PS/PVC/PET:

Peel strength to PP> 9N/15mm. (200℃, 40kg, 1s)

Peel strength to PVC> 9N/15mm. (180℃, 40kg, 1s)

Peel strength to PS> 9N/15mm. (180℃, 40kg, 1s)

Peel strength to PET> 9N/15mm. (200℃, 40kg, 1s)

Product features

High barrier protection against light, loss of moisture and flavours as well as preventing external contamination.

Ideal mechanical properties for embossed surface designs.

Excellent sealing properties against all common plastics.

Good printability with rotogravure or UV flexo inks, that offers a wide range of decorative possibilites.

Lacquered aluminum coil

Lacquered aluminum coil is specially indicated for the development of closures such as pilfer proof, widely used for wine bottles, olive oil, among others. Chalco supplies its product in reels of wide until 1.600 mm, with core of steel or carton up to 500 mm and maximum weight of 6 tonnes.

Specification

Customer can specify its needs in order to choose the best thickness, alloy and temper of the metal.

Aluminium foil from 180 to 400 μm with colourless or coloured lacquer on one or two sides

Coating Properties:

Colorless and coloured lacquer (matt and bright)

Epoxy or vinyl nature

Authorized for contact with foodstuffs (FDA)

Excellent adhesion to aluminium foil (Resistant to adhesive tape test)

Good Flexibility

Epoxy lacquer

Resistant to solvents (ILA-06). Polymerization >30 Double rubs/ MEK.

Resistant to dry heating (ILA-08/5.3) (2min/ 240ºC).

Resistant to boiling water (ILA-08/5.5) (15min).

Resistant to sterilization (specially for pharma caps)

Bending (ECCA T7) < 1T

Coated aluminium foil for bottle neck

Chalco's coated aluminium foil could be used for the protection of capsules or bottle necks for the beverage markets. Thanks to its unique mechanical properties on the market, the coated aluminium foil are ideal for producing embossed designs, which in addition provides a distinctive appearance also makes the labels easie r to handle. And they are safe for use in contact with foodstuff.

It is mainly used to cover the capsule, bottle neck label and label on drink cans of wine, champagne and other bottled drinks.

Specification

Alloy: 8011, 8079

Temper: O

Thickness: 0.04mm up to 0.08mm.

Coating: Primer or coloured lacquer on one side and heat sealing lacquer on the other side.

| Alloy | 8011, 8079 |

| Temper | O |

| Thickness | 0.04mm up to 0.08mm. |

| Coating | Primer or coloured lacquer on one side and heat sealing lacquer on the other side. |

Coating properties

Colorless primer and coloured lacquer (optional) :

Nature nitrocellulose or vinyl modified.

Excellent adherence to aluminium foil

Good results of printing to Nitro and UV lacquer.

The resistance of these lacquers are responsibility of the printer.

Resistant to dry heating (maximum 220℃ 1s)

Resistant to boiling water (30 min room temperature)

Heat sealing lacquer

It is authorized for contact with foodstuff (FDA).

This lacquer can be heat sealed to NC, vinyl, and PVC.

Resistant to boiling water (30 minute room temperature).

Product features

It can be laminated easily with other materials and it can be shaped to the provide protection and decoration as capsules for wine, champagne and other bottled drinks.

High barrier protection against light, liquids and atmosphere preventing external contamination.

Good printability, that offers a wide range of decorative possibilities and adds visual quality to any type of bottle.

Coated aluminum foil for medical blister packaging

Chalco's coated aluminum foil can be used to produce protecti`ve and safe packaging for pharmaceutical applications. Moreover It can be made suitable for different applications like “push through” lids or preformed trays for tablets by using different alloys with different mechanical properties. Such as the blister packs for pharmaceutical applications, cold forming blister packaging, push through 'lids'.Quick Quote

Specification

| Alloy | 8011、8079 |

| Temper | O、H18 |

| Thickness | 0.02mm ~ 0.05mm |

Coating properties

Colorless Primer and Coloured Lacquer

Excellent adhesion to aluminium foil (resistant to adhesive tape test).

Good printing results using nitrocellulose inks and UV inks. (Inks' resistance is responsibility of the printer).

Resistant to heatsealing temperature (max. 220ºC 1s).

Water resistant (30 min at room temperature).

Heatsealing lacquers

Authorized for contact with foodstuffs (FDA).

Water resistant (30 min at room temperature).

Resistant to boiling water (5 min/100ºC).

Lacquer porosity (15 min) < 5 pores/m2 (20g CuSO4 /50cc HCl (35%) /1000cc. H2O).

Sealable to PVC/PVDC. Peel strength to PVC > 7.5 N/15mm. (180ºC, 40 kg, 1s) (Plastic Supports from Alucoat's lab).

Product features

Total barrier protection against light, moisture, oxygen and other gases, and liquids.

Good mechanical protection.

Light weight that allows use the minimum of transport and production space.

Safe for use in contact with foodstuffs (according to European Directives, and FDA).

Coated aluminum foil for closures and caps

Chalco coated aluminum foil is used for anti-theft caps and bottle caps in the pharmaceutical industry. The coated coil is made of special resin to support the rigorous sterilization process in the pharmaceutical and cosmetic industries, and ensure the highest quality of hygiene. In addition, they can be in direct contact with food.

Coated Aluminum Foil is mainly used for bottle caps, caps and vials in the pharmaceutical industry. It also used for the caps and containers, ROPP caps, PP caps, alcohol and drinking anti-theft caps in the production of beverages and cosmetics.

Specifications

| Alloy | EN 8011 |

| Temper | H14, H24 |

| Thickness | 0.18mm up to 0.4mm |

| Width | 200 up to 1200mm |

Coating properties

Colorless and coloured lacquer (matt and bright).

Epoxy or vinyl nature.

Authorized for contact with foodstuff.

Good flexibility.

Epoxy lacquer and polyester.

Deep drawing property

Ideal mechanical properties for deep drawing process (up to 60mm length)

Color coated aluminum foil for roof covering

Chalcocolor coated aluminum foil is used for production of insulation structures for building (roofs, chimneys, among others). Our product to be used in the production of insulation for roof ridges and edges after combination, provides an excellent barrier for humidity, gas and U.V. light.

It can be supplied in a wide range of colors and different qualities of lacquer. It is specially suitable for roofing isolation, it keeps perfect air conditioning and protect against external agents.

| Property | Method | paint |

| Top layer | Coloured lacquer, polyester, PE | |

| Aluminium | 8011/8079/1200/1100/1060 O | |

| Bottom layer | Coloured lacquer, polyester, PE | |

| Standard colours | Wide range of colours RAL | |

| Bending | ECCA 7(0≤T BEND ≤1) | OK |

| Curing | Resistance to MEK | > 50 d.f. |

| Heat Resistance | 240 ℃/2 min. | OK |

| Corrosion Resistance( Neutral Salt Spray) | ASTM B117 (NaCI 5%/35℃ | >500h(According to specification >1000h) |

| U.V. Resistance | ASTM G154(500 h., ; UV -313 4h.60℃/Condensation 4h.40℃) | OK |

Product features

Lacquers have been specially designed by our technical department and provide an excellent resistance to weathering and UV light.

It can be laminated to other materials (foams, plastics, among others) in order to form very high performance insulation and barrier products.

Easy to shape, which do it the best election to special application.

Color coated aluminum foil for furniture decoration

Color coated aluminum foil for furniture decoration is suitable for being laminated with PVC, slats and MDF board, melamine, among others, intended for kitchen furniture. The aluminum coating provides a decorative element while protection. It's available in several colors and brushed finish and it's easily molded, making it the best choice for special applications.

Product features

It is a very good barrier to moisture, gas and light.

Have been specially designed by our technical department and provide an excellent resistance to weathering and UV light.

It can be laminated to other materials (foams, plastics, among others) in order to form very high performance insulation and barrier products.

There is the possibility to incoporate the pre-treatment coating that improves the corrosion resistance and the adherence of the lacquer over the aluminium surface.

Hydrophilic color coated aluminum foil

Hydrophilic aluminum foil accounts for 80% of the aluminum foil volume of air conditioner. It can reduce the noise and ensure the long-term stable heat exchange effect of the air conditioner.

Compared with aluminum fin sheet, the aluminum foil surface has a corrosion resistant hydrophilic layer, so it has corrosion resistance, mold resistance and no odor. Moreover, its heat dissipation efficiency is 5% higher than that of fin aluminum foil, which is a more ideal air conditioning heat exchange material.

Specifications

| Alloy | 1100 1200 3102 8011 |

| Temper | O H22 H24 H26 |

| Thickness | 0.095mm -0.3mm |

| Width | 140mm-1300mm |

| External diameter | 400-1400mm |

| Color | blue, white, gold, as required |

Coating Performance

Film thickness / 1.0-2.0µm (Single side average thickness)

Hydrophilicity /Primary contact angle?10° /Continuous contact angle?20°

Adherence strength Erichsen test (pressed depth 5mm) , no peeling off

Corrosion resistance /Salt&Spray (72 hours) R.N?9.5

Alkali resistance/ Dipped in 20% NaOH under 20°C for 3 minutes. absolutely no blister.

Impregnant resistance / Sample weight loss?1%

Heat resistance/ Under 200°C keep 5 minutes, performance and color unchanged; Under 300°C keep 5 minutes, coating film become a bit yellow

Oil proof/ Dipped in volatile oil for 24 hours, no blister on the coating layer

Coating film odor/ No stranger odor

Product features

High temperature resistant

Weathering resistant

Scrubbing resistant

Sound insulation

Acid or alkali proof

Fireproof

Light weight material is easy to construct and install

Bright colors

Easy molding process, not rusting, etc.

Fin coated aluminum foil

Industrial heat exchangers mainly use aluminum as fins, which requires high deformation capacity and certain strength. It is applicable to large water-cooled or air-cooled equipment such as nuclear power plant, petrochemical industry and power plant. It perfectly supplies the global large-scale industrial heat transfer projects through professional slitting and special annealing process.

Chalco reduced the fin thickness by changing the alloy, but maintains the formability and strength of the fin. In this way, the equipment volume can be reduced and the heat transfer efficiency can be improved. Fin coated aluminum foil shall be used for radiator and air conditioner.

| Alloy | 1050 1060 1100 8011 |

| Temper | H22 H24 H26 |

| Thickness | 0.14mm |

| Width | 200mm |

| Color | blue |

| Surface treatment | Polished/coated/hydrophilic |

Chalco color coated aluminum foil

We supply a variety of color coated aluminium foil products, including those for heat sealing, corrosion resistant epoxies, slip lubes, print primers, release coatings, and others. All coated foil rolls can be produced in gauges/thicknesses ranging from 0.00035” to .010”. Coating thicknesses can be applied up to .002″, and slit width ranging from .250” to 54.50”.

Advantage of coating

We have good processing ability of color coated aluminum foil. A variety of colors and tints are available for our color coated aluminium foil. Durable clear coatings can be customized. High gloss and brilliant appearance adds appeal to foods. Excellent impermeability to water vapor and gas keeps foods and pills dry and original. Strong insulation ability and oxidation resistance avoids flavour loss and extends shelf life of food products.

Packaging advantage

We adopt the packaging mode of outer packaging+inner packaging, with more strict requirements and packaging methods, to ensure that various properties of goods will not be damaged during transportation.

Inner packing: each roll to be wrapped with sack polyethylene and plastic plug.

Outer packing: carton packing, wrap by film then pallet packing.

Contact us

We are committed to providing all customers with the highest quality, the best delivery time and excellent customer service on our color coated aluminum foil products. We hope to have in-depth cooperation with you to provide you with high-quality product customization services. If you want to get the latest quotation and the most favorable price, please contact us.